How to Test the Earth Fault Loop Impedance – Various Methods

Testing and Measuring Earth Fault Loop Impedance using Different Methods

What is Earth Fault Loop Impedance (EFL)?

Earth fault loop impedance refers to the electrical resistance in the earth path of a circuit, measured when a fault occurs between Live conductors and the Earth (Ground). When the Line (Live, Phase, or Hot) wire makes contact with the external metallic body of a machine, an earth fault occurs, and the protective device must trip and isolate the circuit from the mains power supply to protect the person who accidentally comes into contact with the body of that equipment.

The total loop impedance in case of earth fault flowing from the starting point to the ending point *

The total resistance of the earth fault current loop, which starts at the point of earth fault and ends at the origin of the fault, is known as Earth Fault Loop Impedance and is denoted by the symbol (ZS).

When all the metallic casings of equipment are connected via a Circuit Protective Conductor (CPC) to the Main Earth Terminal (MET), which is further linked to the earth electrode through an earth continuity conductor, a properly earthed system is established.

Click image or open in new tab to enlarge

In the event of an earth fault (such as when the Live wire comes into contact with the external metallic part of the equipment) and a person touches that machine, they will not be electrocuted or receive an electric shock due to the presence of a proper earth fault protection system. In this system, the fault current flows back to the earth via the CPC cable.

However, in the absence of earth fault protection (such as RCD/RCBO or GFCI with proper grounding), a person touching the external body of the machine will receive an electric shock, potentially leading to hazardous fire and electrocution. This underscores the importance of electrical earthing and grounding.

Earth fault loop resistance is a critical parameter in electrical installations, indicating the ability of protective devices like circuit breakers and RCDs to quickly and effectively isolate faulty circuits, preventing electrical hazards and ensuring safety. In this article, we will discuss the working and different types of loop tests, as well as how to test the earth fault loop impedance using various ground resistance testers.

Earth Fault Loop Impedance Test and Why is it Important?

The earth fault loop impedance test is a fundamental procedure in electrical testing aimed at evaluating the effectiveness of protective measures within an electrical circuit. This test involves measuring the impedance or resistance encountered by fault current when a fault occurs between live conductors and the earth.

By determining this impedance, electricians will select and install proper and rated protective devices such as circuit breakers, residual current devices (RCDs) and ground fault circuit interrupter (GFCIs) according to the codes to promptly detect and isolate earth faults, preventing electrical hazards.

All related electrical installations, including sockets/outlets, must comply with the safe limits of EFL, TN/TT and local area codes (such as IEC/NEC). Essentially, the earth fault loop resistance test ensures the safety and reliability of electrical installations by verifying that protective measures are functioning as intended in the event of a fault.

In a TT system, the earth electrode is independent of the utility’s neutral conductor. This ensures a dedicated and low-resistance path to earth, enhancing safety and reliability. An RCD must be used instead of a breaker or fuse for shock protection, especially in TT systems, where there are often high external earth fault loop impedances. This is because insufficient fault current may not operate the breaker or trip the fuse.

Higher external earth fault loop impedances are usually associated with TT earthing systems, which don’t provide sufficient fault current to operate fuses or circuit breakers within the required time and an RCD must be used for electric shock protection.

Conversely, in a TN system, the earthing is directly connected to the utility’s neutral conductor, relying on a shared return path. While this system is simpler and more economical to implement, it may present higher impedance and increased risk in fault scenarios. Additionally, please refer to BS 7430:2011+A1:2015 for more information on the proper methods of earthing systems and installations.

If the nominal voltage is up to 1000V AC (or 1500V DC), the earth impedance is expected to be sufficiently low and within the limits of BS 7671, which disconnect the breaker and fuse immediately in case of an earth fault. Otherwise, it is also acceptable if the EFL is <80% of the rated device mentioned in BS-7671. In other words, the maximum value of ZS should not exceed 0.8 times the relevant value for each final and sub-circuit.

The highest measured ZS value for each circuit should not exceed 0.8 of the relevant value in the BS 7671 tables.

In the case of a TT wiring system, it provides good protection against electric shock if it complies according to the following values.

Ra × IΔn ≤ 50 V

- Ra = Total resistance of MET (main earth terminal bar) and CPC (circuit protective cable)

- IΔn = Maximum electric current of the protection system.

It means that if the values of Ra and IΔn are less than 50V, the system is not harmful even if you touch the external metallic frame of equipment during an earth fault (still, don’t do that intentionally). This is because the circuit will be automatically disconnected by the associated MCB or RCB/GFCI.

How to Calculate Earth Fault Loop Impedance?

You may use the following formula to calculate the earth loop impedance:

ZS = ZE + R1 + R2

Where:

- ZS = Earth Fault Loop Impedance – (The impedance of the whole fault path)

- ZE = External Fault Loop Impedance – (The impedance of the fault path at the electricity supplier’s side)

- R1 = Phase (Line) Conductor Impedance – (Resistance of the Line (Phase) conductor in the installation’s circuit)

- R2 = Circuit Protective Cable (CPC) Impedance – (Resistance of the CPC (Earth or ground wire) in the installation’s circuit)

You can follow the test tutorial provided by specifically designed testers in the sections below. Alternatively, you may use a multimeter or other multipurpose tester to measure the values of ZE, R1, and R2 separately. Then, you can add all these values together to obtain the value of ZS, as shown in the formula above.

How to Calculate the Maximum Value of EFL?

The maximum value of earth fault loop impedance (ZMAX) can be calculated using the following formula.

ZMAX = Uo ÷ Ia

Where:

- ZMAX = Max. earth fault loop impedance

- Uo = Nominal phase voltage

- Ia = Mean tripping current of circuit breaker

Example:

“Ia” can be found in the user manual of the protective devices. The values of “Ia” current of available breaker models are typically:

- Type B = 4 × rated current

- Type C = 7.5 × rated current

- Type D = 12.5 × rated current

The tripping current Ia for fuses can be matched and confirmed with the user manual and the latest tables in your local area code regulations.

Example: The maximum earth fault loop impedance (ZMAX) for a Type B breaker in 230V AC circuit is:

4A x 32A = 128A

ZMAX = 230V ÷ 128A

ZMAX = 1.79 Ω

How to Determine the Exact Value of EFL?

IEC (IET Wiring Regulations) provides specific values of EFL for different voltage levels in electrical systems in order to maintain the time required for the protective devices to automatically open during fault condition.

The recommended value of earth fault loop impedance by IEC can be determined using Tables 41.2, 41.3, and 41.4 of BS 7671. Based on these values, you will be able to select the proper-rated circuit breaker and RCDs, which will efficiently disconnect the circuit in case of an earth fault.

The tested, measured, and calculated values of external earth loop impedance (ZE) recommended by Regulation 313.1 may differ from the maximum value provided by the power supply provider which are typically

- TN-S System = 0.8Ω

- TN-C-S System = 0.35Ω

- TT System = 21Ω + the resistance of earth electrode / ground rod

- The supply distributor specifies the maximum external earth fault loop impedance (ZE) for a TN-C-S PME earthing system is 0.35 Ω.

Example 1: What is the maximum value of ZS in a 230V AC TN supply system where the circuit is protected by an MCCB with a rated current “In” of 32A and a tripping current 20 times greater than the rated current, which should isolate the circuit within 0.4 seconds in case of an earth fault?

Solution:

Tripping current of MCCB = 20 times In

= 20 × 32A = 640 Amps.

The maximum earth fault loop impedance for 32A MCCB is

ZS = ( Uo ÷ In ) × CMIN

Where the CMIN = voltage variation factor (Typically 0.95)

(230V × 0.95) – 640 A.

ZS = 0.34 Ω

Example 2: What is the Maximum Value of EFL in case of 63A Type B circuit breaker?

Referring to the table below, the maximum value of earth fault impedance is 1.84. It means, the value of EFL should be equal or less than the specified value for ZS.

Example 3: According to BS 7671:2018+A1:2020 – Table 41.5, the maximum value of earth fault loop impedance (EFL) for an RCD with 30mA tripping operation is 1667* Ohms. *See Table 2, notes, and refer to the related codes.

Example 4: If we are using a 230V AC supply, the tripping time of the RCD/GFCI or the circuit breaker must be equal to or less than 0.4 seconds in the TN system and 0.2 seconds in the TT wiring system.

Table-1 for MCB’s and Fuses

| Values of Earth Fault Loop Impedances for Overcurrent Protective Devices, for Fault Protection (Based on Tables 41.2, 41.3 and 41.4 of BS 7671) | |||||||||||||||

| Rated current (A) | Fuses | Circuit-breakers to BS 3871 or BS EN 60898 | |||||||||||||

| BS 88 (gG) Parts 2 and 6 | BS 1361 or BS 1362 | BS 3036 | BS 88-2 Fuse systems E (bolted) and G (clip in) | BS 88-3 – Fuse system C | Type 1 | Type 2 | Type B | Types 3 and C | Type D | ||||||

| 0.4 s | 5 s | 0.4 s | 5 s | 0.4 s | 5 s | 0.4s | 5 s | 0.4 s | 5 s | 0.4 s and 5 s | |||||

| 3 | … | … | 13.12 | 18.56 | … | … | … | … | … | … | … | … | 12.26 | … | … |

| 5 | … | … | 8.36 | 13.12 | 7.66 | 14.16 | … | … | 8.36 | 12.26 | 9.20 | 5.26 | … | 3.68 | 1.84 |

| 6 | 6.82 | 10.80 | … | — | … | … | 6.57 | 10.24 | … | … | 7.66 | 4.37 | 6.13 | 3.06 | 1.54 |

| 10 | 4.08 | 5.94 | … | … | … | … | 3.91 | 5.75 | … | … | 4.60 | 2.63 | 3.68 | 1.84 | 0.92 |

| 13 | … | … | 1.94 | 3.06 | … | … | … | … | … | … | … | … | … | … | … |

| 15 | … | … | 2.62 | 4.00 | 2.04 | 4.28 | … | … | … | … | 3.06 | 1.75 | … | 1.23 | 0.61 |

| 16 | 2.16 | 3.34 | … | … | … | … | 2.05 | 3.34 | 1.94 | 3.29 | 2.87 | 1.64 | 2.30 | 1.15 | 0.58 |

| 20 | 1.42 | 2.33 | 1.36 | 2.24 | 1.41 | 3.06 | 1.42 | 2.36 | 1.63 | 2.70 | 2.30 | 1.31 | 1.84 | 0.92 | 0.46 |

| 25 | 1.15 | 1.84 | … | … | … | … | 1.08 | 1.84 | … | … | 1.84 | 1.04 | 1.47 | 0.74 | 0.37 |

| 30 | … | … | 0.92 | 1.47 | 0.87 | 2.11 | … | … | … | … | 1.53 | 0.87 | … | 0.61 | 0.31 |

| 32 | 0.83 | 1.47 | … | … | … | … | 0.83 | 1.47 | 0.77 | 1.31 | 1.44 | 0.82 | 1.15 | 0.58 | 0.29 |

| 40 | 0.65 | 1.08 | … | … | … | … | … | 1.08 | … | … | 1.15 | 0.65 | 0.92 | 0.46 | 0.23 |

| 45 | … | … | 0.46 | 0.77 | 0.47 | 1.27 | … | … | … | 0.83 | 1.02 | 0.58 | 0.82 | 0.41 | 0.20 |

| 50 | 0.48 | 0.83 | … | … | … | … | … | 0.83 | … | … | 0.92 | 0.52 | 0.73 | 0.37 | 0.18 |

| 60 | … | … | … | 0.56 | … | 0.90 | … | … | … | … | … | … | … | … | … |

| 63 | 0.36 | 0.66 | … | … | … | … | … | 0.66 | … | 0.58 | 0.72 | 0.41 | 0.58 | 0.29 | 0.14 |

| 80 | 0.24 | 0.46 | … | 0.40 | … | … | … | 0.46 | … | 0.42 | 0.57 | 0.32 | 0.46 | 0.23 | 0.11 |

| 100 | 0.18 | 0.34 | … | 0.29 | … | 0.42 | … | 0.37 | … | 0.32 | 0.46 | 0.26 | 0.37 | 0.18 | 0.09 |

| 125 | 0.14 | 0.26 | … | … | … | … | … | 0.27 | … | … | … | … | 0.30 | 0.14 | 0.07 |

| 160 | 0.11 | 0.20 | … | … | … | … | … | 0.22 | … | … | … | … | … | … | … |

| 200 | 0.8 | 0.15 | … | … | … | … | … | … | … | … | … | … | … | … | … |

Note: Suitable values for protective devices can be selected using BS EN 60898 for MCBs and BS EN 61009-1 for RCCBOs. For more details, refer to the how to size a circuit breaker?

Table-2 for RCDs

| Maximum earth fault loop impedance (ZS) for non-delayed and time delayed ‘S’ Type RCDs to BS EN 61008-1 and BS EN 61009-1 for Uo of 230 V (See Regulation 411.5.3) | |

| Rated Residual Operating Current (mA) | Max. Earth Fault Loop Impedance (ZS) Ohms |

| 30 | 1667* |

| 100 | 500* |

| 300 | 167 |

| 500 | 100 |

|

|

Table-3 for Tripping Time in seconds (AC and DC Breakers)

| System | 50V < Uo ≤ 120V – seconds | 50V < Uo ≤ 230V – seconds | 50V < Uo ≤ 400V – seconds | 50V < Uo > 120V – seconds | ||||

| AC | DC | AC | DC | AC | DC | AC | DC | |

| TN | 0.8 | … | 0.4 | 5. | 0.2 | 0.4 | 0.1 | 0.1 |

| TT | 0.3 | … | 0.2 | 0.4 | 0.07 | 0.2 | 0.04 | 0.1 |

- Related Post: How to Measure Resistivity of Earth Using Wenner Method?

How to Test the Earth Fault Impedance using Earth Testers?

You may use different earth-loop impedance testers such as 3-Wire Digital PSC and loop impedance testers (e.g., Fluke 1663, 1652C, Kyoritsu 5406A, KEW 5410, 4140, 4118A, and other brands), or you may use the two-wire loop tester like Megger LT4-425.

Click image or open in new tab to enlarge

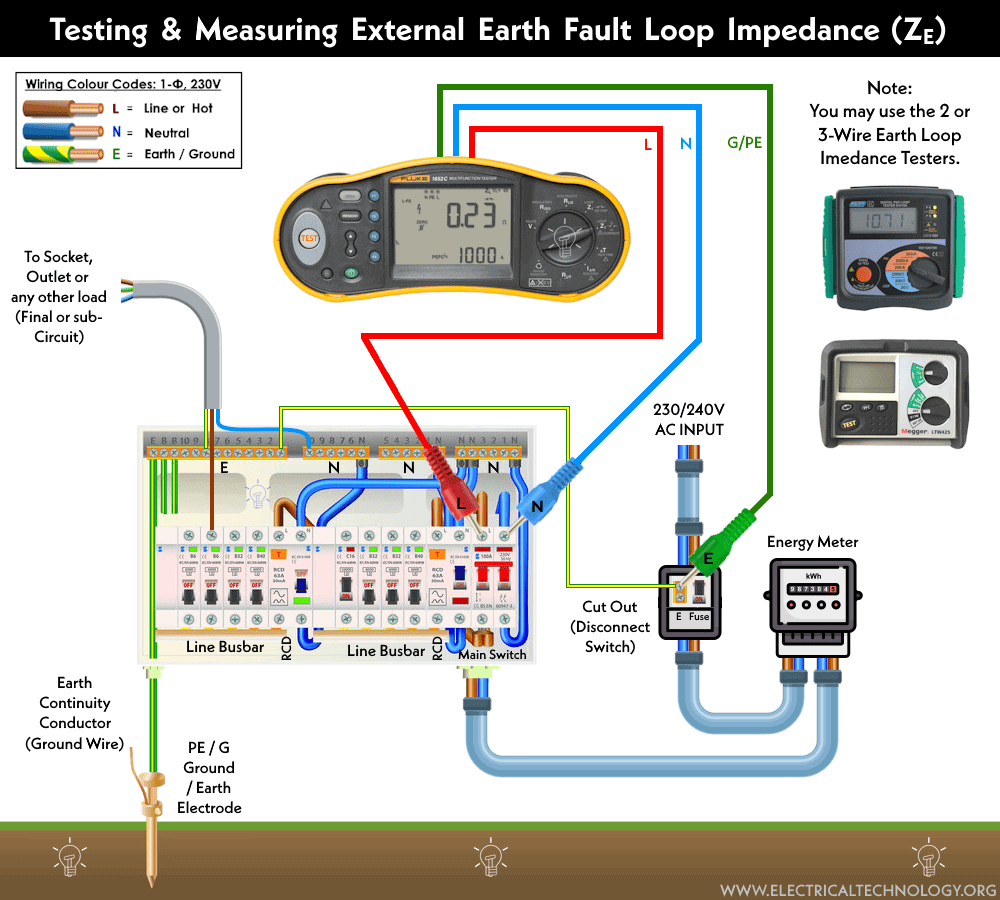

Measuring External Fault Loop Impedance “ZE“

For testing and measuring “ZE“, we have used the three wire tester. You may use the 2-wire tester if needed.

- Rotate the rotary switch to the select the “Z – No Trip” position. This will prevent the unwanted tripping of RCDs, ELCBs, GFCIs, etc. if the circuit is protected by these devices.

- Press the F1 to select the L-PE (Line – Protective Earth).

- Press F3 to select the RE (ground or earth resistance).

- Connect the protective earth (PE or G) probe to the earth bar terminal in the consumer unit/main panel. You may also connect the PE probe to the earth/ground bar on the cut-out or disconnect switch before the energy meter.

- Now, connect the ‘N’ probe to the Neutral (N) terminal on the main fuse-breaker switch in the consumer unit/main panel.

- Finally, connect the ‘L’ probe to the Line (Phase or Hot) terminal on the main switch.

- Press and release the Test button. The tester will display the result. Observe and note the reading. In our case, it was 0.23Ω.

-

- The loop impedance is displayed in the upper (primary) screen.

- The earth resistance is displayed in the lower (secondary) screen.

-

In the two-wire loop test method, you will only have to connect the Green and Red probes to the outgoing Line and Neutral terminals respectively in the main panel/consumer unit.

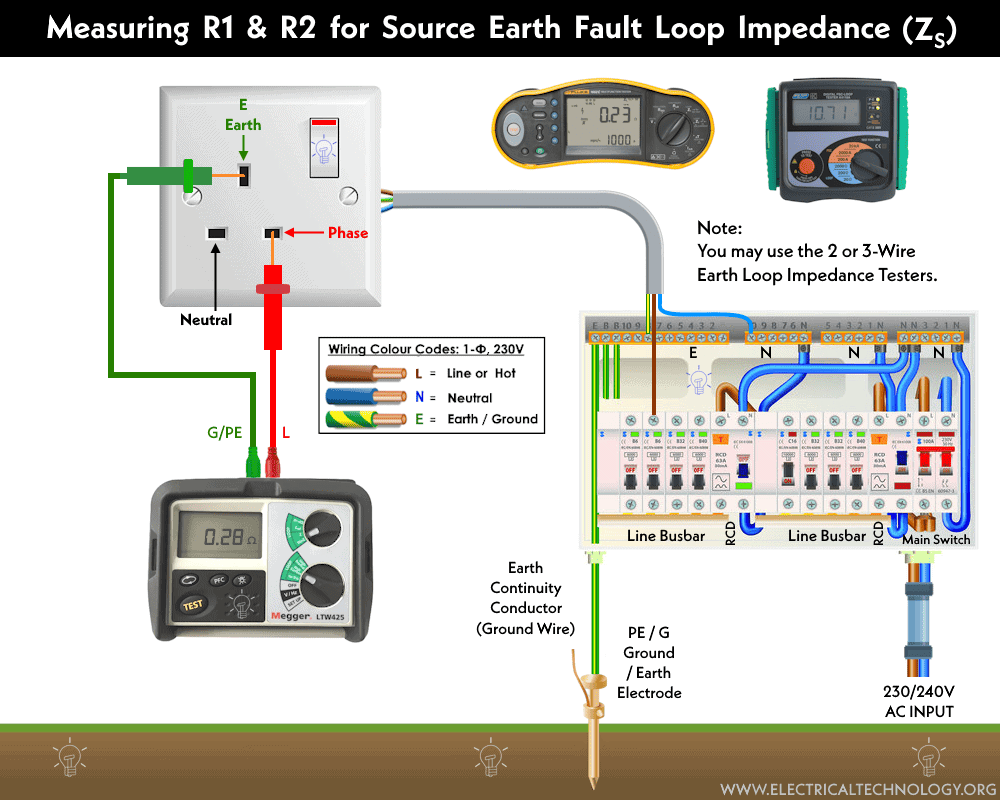

Measuring ZS, R1 and R2 for Total Earth Fault Loop Impedance

For testing and measuring the source impedance and overall resistance, we have used the two wire tester. You may use the 3-wire tester if required.

Click image or open in new tab to enlarge

- Rotate the lower (big) rotary switch in the loop section to ‘No Trip’. You may select other options depending on the test requirement, such as High Current, High Resolution, etc.

- Rotate the upper (small) rotary switch in the loop section to ‘MaxZ’. You may select other options depending on the test requirement, such as Z, Zref, R1 + R2.

- Connect the Red probe from the loop resistance tester to the Line (Phase or Hot) slot on the three-pin safety socket (BS-1363). In the US 120V/240V outlet, the narrow slot is Live (Hot).

- Now, connect the Green (PE-G) probe from the loop impedance tester to the earth terminal (E) on the socket/outlet.

- Press and release the Test button. The multifunction meter will display the result. Observe and note the reading. In our test case, it was 0.28 Ω.

Note:

It is important to connect the RCD and GFCI, etc., before conducting the test. If the tester does not have a “No-Trip” built-in feature, you will need to verify the values of ZS for each circuit and ensure they fall within the safe limits specified in your local area code (e.g., BS 7671).

Temporarily bridge out unless you are using the Kyoritsu K4120 (discontinued) with RCD/ELCB Lock.

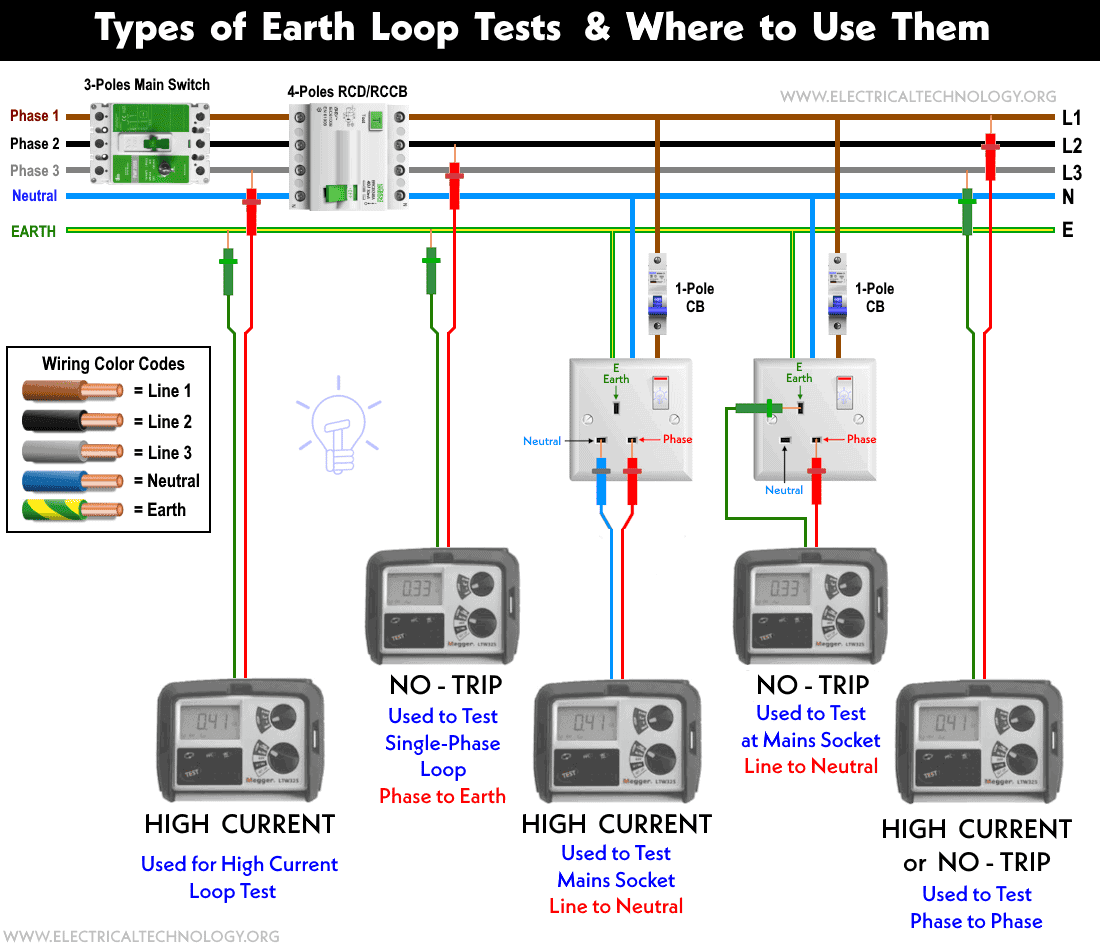

Types of Earth Fault Impedance Test Methods

Click image or open in new tab to enlarge

2-Wire High Current Test:

The 2-wire high current test is a basic and most used method for determining earth loop impedance in electrical installations. In this test, a high current up to 20A is passed through the circuit under test using only two connections: the Line and Neutral. By applying a high current, the resistance of the circuit is accurately measured, providing essential information about the integrity of the electrical system.

This method is particularly effective for detecting any potential faults or irregularities in the circuit, such as loose connections or damaged wiring. It allows electricians to identify areas of concern and take appropriate corrective actions to ensure the safety and reliability of the electrical installation.

2-Wire “No-Trip” DC Saturation Test:

The 2-wire “No-Trip” DC saturation test is a specialized method used to measure earth loop impedance without causing RCD (Residual Current Device) or circuit breaker tripping. Unlike traditional tests, this method injects a direct current (DC) signal, which saturates the magnetic components of the RCD or circuit breaker, preventing them from operating.

By using this technique, electricians can accurately measure earth loop impedance without disrupting the electrical system’s operation. This test is particularly valuable in situations where maintaining power supply continuity is critical, such as in essential services or sensitive equipment environments.

Additionally, it ensures that the impedance measurement is accurate and reliable, allowing for precise evaluation of the electrical installation’s safety and compliance with regulatory standards. This test has limitations due to the increasing number of electronic RCDs being used instead of the old electromechanical RCDs.

3-Wire “No-Trip” Test:

The 3-wire “No-Trip” test is a comprehensive method for measuring earth loop impedance in electrical systems without causing RCD or circuit breaker tripping. This test involves connecting the line, neutral, and earth wires to the tester, allowing for accurate measurement of the impedance across the entire circuit.

By utilizing three connections, the test provides a thorough assessment of the electrical installation’s integrity, identifying any potential faults or abnormalities that may compromise safety or performance.

This method is widely used in both residential and commercial applications because it offers a time-saving and quick approach to identifying earth loop resistance. Additionally, it indicates the reverse polarity and bypasses tripping in both electromechanical and newer electronic RCDs, RCBOs and MCBs.

2-Wire “No-Trip” Test:

The 2-wire “No-Trip” test is a simplified method for measuring earth loop impedance in electrical circuits without bypassing the RCD or RCBO to avoid unwanted tripping. This test involves connecting only the Line and Earth wires to the tester, bypassing the neutral connection.

By using this approach, electricians can obtain a quick and accurate measurement of earth loop impedance without disrupting the electrical system’s operation. Keep in mind that due to the 2-wire connection, this method can’t be used to indicate the reverse polarity as compared to the 3-wires No-Trip method.

This method is particularly useful in situations where access to the neutral wire is limited or when conducting a rapid assessment of multiple circuits. It provides a convenient solution for ensuring the safety and compliance of electrical installations while minimizing downtime and disruption.

4-Wire Grid Impedance Test:

The 4-wire grid Kelvin connection impedance test is an advanced with high degree of accuracy method used to measure earth loop impedance in complex electrical systems.

This test involves utilizing four connections: Line, Neutral, and two additional sense wires. The sense wires are used to measure the voltage drop across the circuit under test accurately, eliminating any errors introduced by the resistance of the test leads. In short,

- The 4-wire grid loop impedance test is highly accurate because it also measures and eliminates the resistance value of test leads and contacts.”

- “The test ranges from 10 mΩ with 1kA.”

- “There is no ‘no-trip’ option available in this method.”

- “The test performer must protect themselves from shock hazards while obtaining the values of ZE and ZS.

By employing this technique, electricians can obtain highly precise measurements of earth loop impedance, even in large or intricate electrical installations. The 4-wire grid impedance test is essential for ensuring the safety, reliability, and compliance of critical infrastructure, such as industrial plants, commercial buildings, and healthcare facilities, where precision and accuracy are paramount

Related Posts:

- Electrical Earthing and Grounding – Methods, Types and Installation

- Protective Multiple Earthing (PME) – TN-C-S – (MEN) and PNB

- How to Measure Earth Loop Resistance Using Ammeter and Voltmeter?

- Design of Grounding / Earthing System in a Substation Grid

- Why are Salt and Charcoal Added in Earthing Pit for Grounding?

- What is the Purpose of Ground Wire in Overhead Transmission Lines?

- Difference Between Grounding, Earthing and Bonding

- What is the Difference Between Neutral, Ground and Earth?

- Difference Between Real Ground and Virtual Ground

- Why is the Grounding Wire Bare and Not Insulated?

- Why is Copper Rod Used as Ground Rod in Grounding / Earthing System?