How to Design a Solar Photovoltaic Powered DC Water Pump?

A Guide on Designing a Solar Photovoltaic Powered DC Water Pump

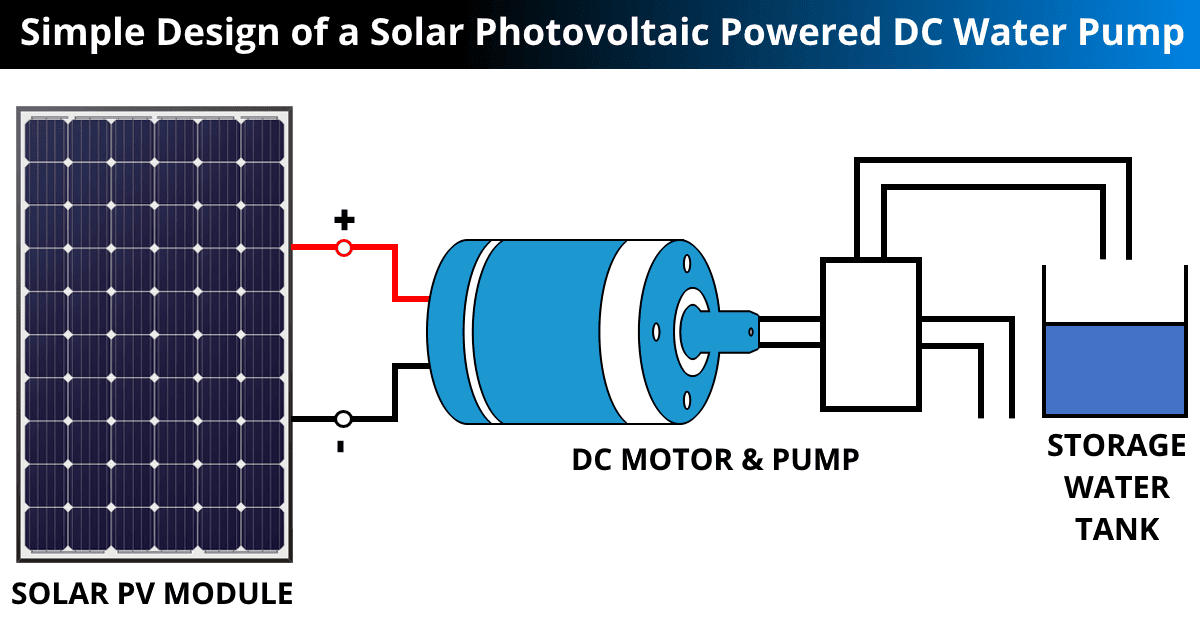

Typical Design of Solar Powered DC Motor Pump

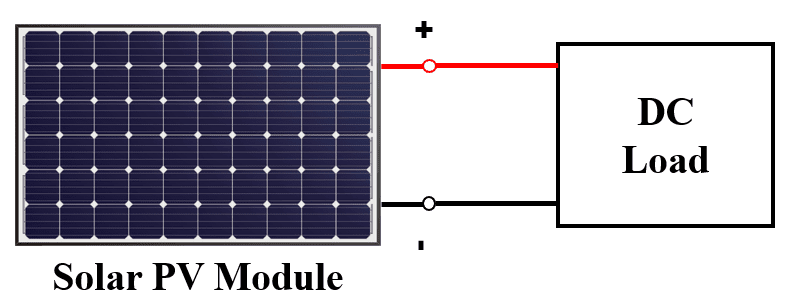

The simplest type of PV system one could ever design is by connecting single or multiple PV modules directly to the DC load as shown in figure 1 below.

The overall capacity of the modules is such that it can supply power only during the sunshine hours. No special arrangement is made to have the maximum utilization of the modules by tracking the maximum power point of the modules with a charge controller throughout the day.

Such a system is an unregulated system as the power output from the modules changes due to change in the sunshine hours and no backup battery arrangement is made to supply energy demand during night-time operation. Such a system is more suitable for domestic applications such as pumping of water using a DC motor water pump.

As stated, such a system can be used for pumping of water especially in the application of irrigation. If we need water at night, then we can use the stored energy in the battery to pump the water during night time. But as we know that batteries can only be charged during the day sun-shine hours.

So why should we charge batteries if we can utilize that available solar energy to pump the water right away during sunshine hours? On the other hand, we know that batteries are not cheap and would also require a power electronics circuit like a charge controller which would add to the cost. So, by utilizing the available solar energy right away during sunshine hours to pump the water we can eliminate the cost and space required for the battery and charge controller in this standalone application.

The design of such a system is very simple as we have to match the power and voltage rating of the PV module to that of the DC pump motor so when the module receives the solar radiation the pump will draw the water and store it in the tank. Such a system can also be designed for an AC motor of different power ratings which is available in the market.

But the AC motor pump will require an inverter (DC – AC) circuit to invert the DC power generated by the PV module into AC power to run the motor. Also, the inverter power rating should be properly matched with that of the AC motor and PV module.

Related Posts:

- How to Design and Install a Solar PV System?

- Automatic Plant Watering & Irrigation System – Circuit, Code & Project Report

Requirements of Solar Powered DC Water Pump

Now before we begin with the design of the system for water pumping it is important to understand some terms which are closely related to design such a standalone system.

- Daily water requirement (m3/day): The water requirement may vary daily, monthly, and seasonally. The amount of water required per day determines the cost and the size of the system. So, if the water requirement varies per day than the weekly or monthly average can be taken for design calculation. But maximum water requirement should be considered, because if the system can fulfill the peak water demand than it can fulfill the regular demand.

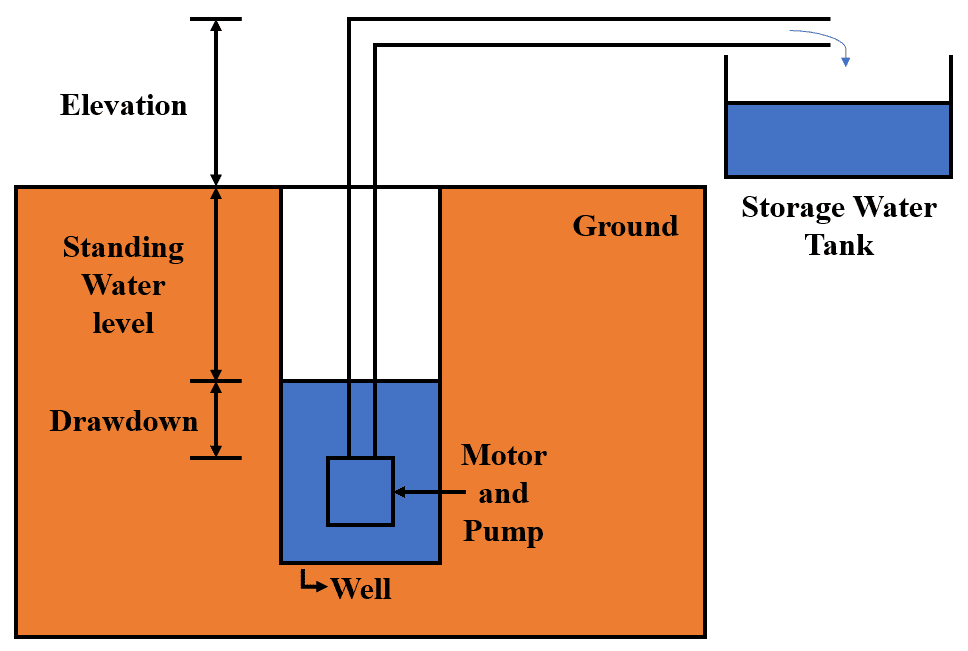

- Total Dynamic Head (TDH) (meters): This is the most important parameter for the design of the pumping system. It is the effective pressure at which the water pump must operate and it is measured in meters. It has two sub-parameters first one is the total vertical lift and the other one is the total frictional losses. Now further, the total vertical lift is the summation of three parameters shown in figure 3 below as; elevation, standing water level, and Drawdown.

- The elevation is the measure of the difference between the points i.e. between the ground and the height at which the water is to be discharged.

- Standing Water Level is the difference between the water level in the well and the surface ground.

- Drawdown is the measure of the height from which the water level drops down due to pumping the water out.

- Frictional losses (meters): This is the pressure that is required to overcome the friction in the pipe present between the water pump outlet to the point of water exit. It is added in the total vertical height to obtain the value of Total Dynamic Head (TDH) and is measured in meters. Multiple factors contribute to the cause of the frictional losses such as the size of the pipe, type of fittings, air present in the pipe, number of bends, flow rate, etc. If the water discharge point is close to the well than an approximation value of the frictional loss is used for the calculation. For example, if the discharge point is within 10 m of the well, 5 % of the total vertical lift is taken as the frictional loss.

Related Post:

- A Complete Guide About Solar Panel Installation with Calculation & Diagrams

- Basic Components Needed for Solar Panel System Installation

Steps to Design a Photovoltaic Powered DC Water Pump

All the above parameters are very useful for the design of the system for water pumping using solar PV modules. Now let us see how these parameters and different steps can be useful to design such a standalone system. The system design can be done in five steps as follows;

- Step 1: Determine the daily water requirement in (m3/day)

- Step 2: Calculate the Total Dynamic Head (TDH) required for pumping the water.

- Step 3: Calculate the total hydraulic energy required per day (Watt-hour/day) for pumping the water.

- Step 4: Calculate the solar radiation available at the site.

- Step 5: Calculate the size and number of PV modules required, the motor rating, its efficiency, and losses.

Related Posts:

- Water Level Indicator Circuit Diagram- Two Simple Projects

- Fully Automatic Water Level Controller using SRF04

Example & Calculation for Designing a Solar Powered DC Water Pump

To understand this simply let us take a design example where we need 50 m3 water per day from a depth of 20 m. It has elevation, standing water level, and drawdown of 10 m, 10 m, and 4 m respectively.

Water density is 1000 kg/m3 and acceleration due to gravity (g) is 9.8 m/s2. The peak power rating of the solar module is 36 WP, as the modules do not operate at its rated peak power capacity so the operating factor is 0.75. The pump efficiency is around 40 % and the mismatch factor is 0.85 as the modules do not operate at the maximum PowerPoint.

Note that the mismatch factor should be taken as 1 if we are using an MPPT along with the charge controller, but in our case mismatch factor is 0.85 as we are directly connecting the PV modules to the DC pump motor.

Step 1: Determine the daily water requirement in (m3/day)

Daily water requirement = 50 m3/day

Step 2: Calculate the Total Dynamic Head (TDH) required for pumping the water.

Total vertical lift = Elevation + Standing Water Level + Drawdown

Total vertical lift = 10 m + 10 m + 4 m = 24 m

Frictional loss = 5 % of the total vertical lift = 24 × 0.05 = 1.2 m

Total Dynamic Head (TDH) = Total vertical lift + Frictional loss

Total Dynamic Head (TDH) = 24 m + 1.2 m = 25.2 m

Step 3: Calculate the total hydraulic energy required per day (Watt-hour/day) for pumping the water.

Hydraulic energy required = Mass × g × TDH

Hydraulic energy required = Density × Volume × g × TDH

Hydraulic energy required = 1000 kg/m3 × 50 m3/day × 9.8 m/s2 × 25.2 m = 3,430 Wh/day

Step 4: Calculate the solar radiation available at the site.

Solar radiation available at the site (No. of hours of peak sunshine per day) = 6h/day (1000 W/m2 equivalent)

Peak sun hours are most commonly used as they simplify the calculations. Do not get confused with the “Mean Sunshine Hours” and “Peak Sun Hours” which you would collect from the meteorological station. The “Mean sunshine hours” indicate the number of hours the sunshine’s were as the “Peak sun hours” is the number of hours the actual amount of energy received in KWh/m2/day.

Step 5: Calculate the size and number of PV modules required, the motor rating, its efficiency, and losses.

Total wattage of PV panel = Total hydraulic energy / No. of hours of peak sunshine per day

Total wattage of PV panel = 3,430 ÷ 6 = 572 W

Total wattage of PV panel considering system losses = Total wattage of PV panel ÷ (Pump efficiency × Mismatch factor)

Total wattage of PV panel considering system losses = 572 ÷ (0.40 × 0.85) = 1,682.35 W

Total wattage of PV panel considering the operating factor of the PV module = Total wattage of PV panel considering system losses / Operating factor

Total wattage of PV panel considering operating factor of the PV module = 1,682.35 ÷ 0.75 = 2,243.13 W

No. of PV panels required of 36 WP = Total wattage of PV panel considering the operating factor of the PV module ÷ 36

No. of PV panels required of 36 WP = 2,243.13 ÷ 36 = 62.30 = (63 round figure)

Power rating of the DC motor = Total wattage of PV panel considering operating factor of the PV module ÷ 746 W (i.e. 1 hp) = 3 hp motor

The arrangement of the panels in series and parallel can be done based on the voltage and current rating of the module and the DC motor. Such a system can also be designed with an MPPT circuit and inverter for the AC motor but it is important that its efficiency and power rating should be taken into consideration while designing the system.

Related Posts:

- How much Watts Solar Panel We need for our Home Electrical appliances?

- Types of Solar Panels and Which Solar Panel Type is Best?

Conclusion

We studied a simple and economical approach to design a solar PV powered based DC water pumping which requires limited components, no requirement of batteries and controller. We briefly studied basic terms related to water pumping and detailed design calculations to pump the required level of water for irrigation purposes. Such a system can also be designed using an AC motor and can be implemented at domestic, residential, and commercial levels.

Related Posts:

- How to Control Water Heater using Switches?

- Rain Alarm Circuit – Snow, Water and Rain Detector Project

- Series Connection of Solar Panel with Auto UPS System

- Parallel Connection of Batteries with Solar Panel

- Blocking Diode and Bypass Diodes in a Solar Panel Junction Box

- Basic Components Needed for Solar Panel System Installation

- How to Connect Automatic UPS / Inverter to the Home Supply System?

Is your calculation on the Hydraulic Energy requirement correct?

The whole value shall be divided by 3.6*10^6 for KWh/day or 3.6*10^3 for Wh/day

Please write on OFF-Grid and ON-Grid system and water pump based on solar power system. Thanks