MPPT Solar Charge Controller – Working, Sizing and Selection

What is Maximum Power Point Tracking (MMPT) Solar Charge Controller?

What is Maximum Power Point Tracking Or An MPPT Charger?

The MPPT or ‘Maximum Power Point Tracking‘ controls are much more sophisticated than the PWM controllers and allow the solar panel to run at its maximum power point or, more precisely, at the optimum voltage for maximum power output. Using this smart technology, MPPT Solar Charge Controllers can be up to 30% more effective based on the attached solar panel’s voltage and voltage.

As a general reference, MPPT charging controllers can be used on all higher power systems using two or more solar panels or if the panel voltage (Vmp) is 8V or higher than the battery voltage-see full definition below.

The MPPT is essentially an effective DC to DC converter to maximize a solar panel’s power output. The first MPPT was invented in 1985 by a small Australian firm named AERL and is now useful in nearly all grid-connected solar inverters and many solar charge controllers.

The MPPT solar charge controller’s operating theory is elementary because of the changing degree of sunlight (irradiance) on the solar panel during the day. The panel voltage and current vary continuously. To obtain the most electricity, the highest power point tracker sweeps along the panel voltage to find the ‘sweet spot’ or the optimum combination of voltage and current to provide the most power. The MPPT is programmed to continuously monitor and change the voltage to produce the most electricity, no matter what weather conditions.

Notice that usually, only high-end MPPT controllers will detect partial shading or monitor several power points. By using this technology, solar panel performance improves, and the amount of energy produced can be up to 30% higher than the PWM solar charge controller.

Related Posts:

- Basic Components Needed for Solar Panel System Installation

- How to Calculate the Right Size of Solar Charge Controller? PWM & MPPT

The Operational Principle of the MPPT Solar Charge Controller

The output of the photovoltaic array is not linear. It determines by the amount of sunshine, the atmosphere’s temperature, and the load state.

In a steady sunlight intensity and environmental temperature, the photovoltaic array can operate at various output voltages. However, it can achieve the photovoltaic array’s performance quality at a limit of just one output voltage. At this point, the photovoltaic array’s operating point exceeds the highest threshold of the output power voltage curve, which is considered the “Maximum Power Point.”

Therefore, it is necessary to change the photovoltaic array’s operating point to keep it close to the full power point to increase its overall performance. This concept is known as “maximum power point tracking.”

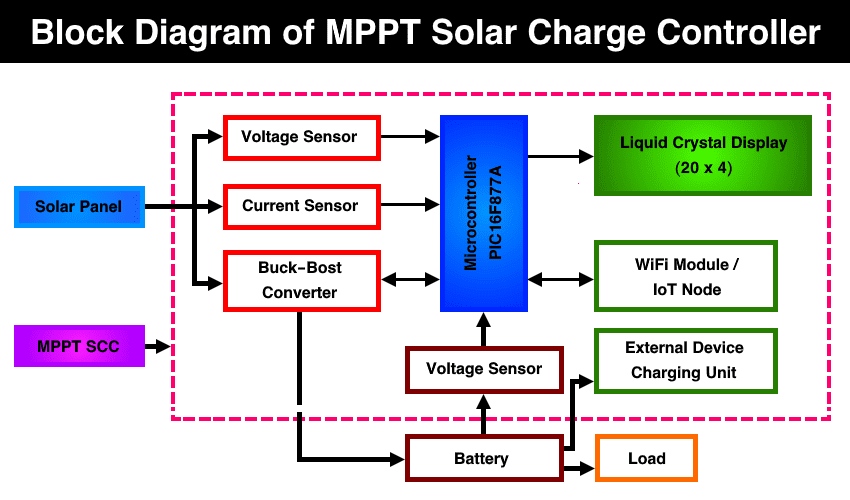

Following is the typical block diagram of MPPT solar charge controller.

Related Posts:

- How to Design and Install a Solar PV System?

- Calculation & Design of Solar Photovoltaic Modules & Array

Performance & Benefits of the MPPT Solar Charge Controller

Now, let’s equate the MPPT Solar Charge Controller to the General Solar Charge Controller.

The General Solar Charge Controller is like a manual car gearbox. If we did not appropriately raise the gearbox as the engine speed increased, the car’s speed would undoubtedly be affected.

Until distribution, It must set the charging parameters of the general solar charge controller. However, the MPPT Solar Charge Controller can monitor the solar panel’s full power point in real-time to achieve maximum performance. When observing the maximum power point, the higher the voltage, the higher the peak power and the higher the charging efficiency.

The solar power system’s performance integrated with the MPPT solar charge controller is 50 percent higher than that of the conventional solar charge controller. However, according to realistic assessment, this number is 20 percent to 30 percent, based on the surrounding atmosphere and electricity loss.

In conclusion, due to construction costs, the solar panel area mounted in RV will be reduced. Also, there would be a significant lack of productivity due to the RV solar panel’s flat installation.

It must also use an appropriate solar charge controller to achieve the solar RV system’s maximum performance.

Related Posts:

- How Much Watts Solar Panel You Need for Home Appliances?

- A Complete Guide About Solar Panel Installation. Examples & Diagrams

Sizing an MPPT Solar Charge Controller

Let us understand this with a basic example. See the next example for more details.

Suppose you have 4 x 100 Watt rooftop solar panels and all are connected in series. each of the panels has an open-circuit voltage of 22.5V. What MPPT controller rating is right?

Answer-

The series voltage will be= 22.5 x 4

V = 90 V

The voltage rating written on the MPPT controller should be 90V or the controller should accept 90 V

Since MPPT controllers limit their performance, you can render the array as big as you want, and the controller can restrict the output. However, this means that the machine is not as effective as it should be. MPPT controllers will have an amp read with it, e.g., a 40-amp MPPT controller. If the panels can generate 80A of current, the MPPT charge controller can only generate 40A of current, no matter what.

MPPT controllers will have an amp read with it, e.g., a 40-amp MPPT controller. Unlike PWM, the input voltage rating of MPPT controllers is much higher than the battery banks that charge it. It is due to the unique feature of the MPPT controller to lower the voltage to the bank voltage of the battery and then raise the current to make up for missing power. You don’t have to use high input voltage to prevent series connections in small systems, but this is very useful in larger systems.

Let’s assume the controller mark indicates that it can accommodate 12V or 24V battery banks. Look for the importance of Rov. For example, if it is Rov-40, the current is the rate at 40 amps.

Thirdly, we should look at the highest solar input voltage. For example, if the MPPT Controller will accommodate 100 volts of input, it can take up to 100 volts and switch it down to your 12V or 24V battery. Let’s presume you’ve got 4 x 100 Watt panels in series, each with an open-circuit voltage of 22.5V. The 4 of the sequence will be 4 x 22.5 V = 90 Volts, which the controller will consider.

Related Posts:

- Blocking Diode and Bypass Diodes in a Solar Panel Junction Box

- How to Make a Simple Solar Cell? Working of Photovoltaic Cells

Example

Let us understand this with an example here. Suppose a room has the following DC loads which are rated at 24 V; four 25 W lamps and two 25 W fan

All the above-mentioned loads are powered by two parallel-connected PV modules, each PV module has a maximum power point current IMP of 5 A and short-circuit current ISC of 8 A. Now we have to find the nominal system voltage, nominal PV array current, and Nominal load current of the solar charge controller?

Total DC load = (No. of lamps × Wattage of each lamp) + (No. of fans × Wattage of each fan)

Total DC load = (4 × 25) + (2 × 25) = 100 + 50 = 150 W

The nominal system voltage of the solar charge controller is the same as the rated voltage of the load and the panel array.

Nominal PV array current = 2 × 8 (short-circuit current of each PV module is 7 A and are connected in parallel)

Nominal PV array current = 16 A

Considering the safety factor of 1.25 the Nominal PV array current is 1.25 × 16 = 20 A

Nominal load current = Total DC load / Nominal system voltage = 150 / 24

Nominal load current = 6.25 A

This way, you need a 6.25A MPPT solar charge controller for the PV system. See more solved example for sizing PWM and MMPT Charge controller in the previous post.

Related Posts:

- Series, Parallel & Series-Parallel Connection of Solar Panels

- How to Wire Solar Panels in Series-Parallel Configuration?

What are the different types of solar charger controller?

Three types of the solar charge controller

1) Simple 1 or 2 Phase Controls: has switched transistors to regulate the voltage in one or two steps.

2) PWM (pulse width modulated): this is the traditional form of the charge controller, e.g., xantrex, Blue Sky, and so on. They are the industry norm at the moment.

3) Maximum power point tracking (MPPT): MPPT identifies the optimum operating voltage and amperage of the solar panel display and matches that of the electrical cell bank.

How to Choose the Best Charge Controller for a Job

MPPT vs. PWM charge controllers

MPPT

MPPT (maximum power point tracking) is modern and more effective technology. As solar panel wattage and voltage rises, more and more panels need MPPT charge controllers.

With MPPT controllers, the incoming solar power passes in at a comparatively higher voltage, and the controller reduces the voltage for the correct charging of the battery. Incoming current increases proportionally with negligible losses, resulting in a highly effective solar charger.

Related Posts:

- How to Design a Solar Photovoltaic Powered DC Water Pump?

- Parameters of a Solar Cell and Characteristics of a PV Panel

PWM

PWM (pulse-width modulation) charge controllers depend on older, less reliable hardware and enable you to adjust the solar panel’s voltage to the battery voltage. E.g., if you were to run a nominal 12-volt solar panel through a PWM charging controller, you need a 12-volt battery bank.

PWM controllers are not nearly as reliable and can lose about 20% of the incoming power due to a lack of efficiency. E.g., a 100-watt/12-volt panel outputs about 5.5 amps at 18 volts in peak conditions. Using a PWM controller will reduce the power to about 14.5 volts at 5.5 amps or 80 watts (14.5V x 5.5a = 80 watts).

There are restrictions about equipment choices, including the use of nominal 12 or 24-volt solar panels. Usually, PWM controllers are smaller in size and have firm limits on available equipment choices because they need the same voltage as the battery bank.

Because of this, most of our residential customers are sticking to MPPT controllers for larger systems. PWM charge controllers are also famous for smaller applications such as RVs, small off-grid cabins, and remote industrial sites requiring limited electricity quantities.

Equipment Compatibility

We can match charge controllers to solar installations with identical electrical characteristics. To pick the best controller, see the following attributes:

- Input voltage: the highest voltage the controller can bear. Generally ranges from 100 to 600 Vdc for MPPT charging controllers.

- Battery voltage: the voltage of the charge controller must be consistent with the battery’s bank voltage. Most small controllers are 12V or 24V, where larger controllers will usually set to 12/24/36/48 volts.

- Current: full charge amps, e.g., 100 amps for FM100 AFCI

- Type of battery: make sure the charge controller is rated to accommodate the kind of battery you are using (most charge controllers get designed for lead-acid batteries, so this point is significant for Li-ion.)

Related posts:

- How to Wire Batteries in Series-Parallel to a Solar Panel?

- How to Wire Batteries in Parallel to a Solar Panel and UPS?

Code-compliance & safety

Check that the controller has get accredited to conform with municipal building standards and safety legislation. Look for the following information:

- UL listed to UL 1741

- Ground fault protection (GFCI)

- UL 458 (for mobile applications)

- Arc fault protection (AFCI)

Online monitoring

Most controllers can bind to a tracking service so that you can verify the performance of your device remotely. Explore compatible tracking portals to ensure they provide all the functionality you need to track your device’s success. In certain instances, remote monitoring & control will require additional hardware.

Communication

Many charge controllers will network with inverters, battery displays, auto generator starters, li-ion batteries, and so on. Check the controller’s networking capability to make sure it plays well with other aspects of the device.

Auxiliary Control

Auxiliary control enables the controller to automatically disconnect other device components depending on criteria defined by the end-user. It is useful for monitoring wired devices such as automatic starter switches, load diversion, and more. It usually involves the addition of adequately graded relays to power your systems.

Efficiency & Self-Consumption

The charge controller itself absorbs electricity, which means that its signal processing is not 100% reliable. Look for low self-consumption and high-performance charge controllers. Most MPPT charge controllers are 98 percent effective or better, while PWM controllers and lower-cost MPPT solutions are behind the mark.

Related Posts:

- How to Wire Solar Panel to 12V DC Load and Battery?

- How to Wire Solar Panel to 120-230V AC Load and Inverter?

Applications of MPPT Solar Charge Controllers

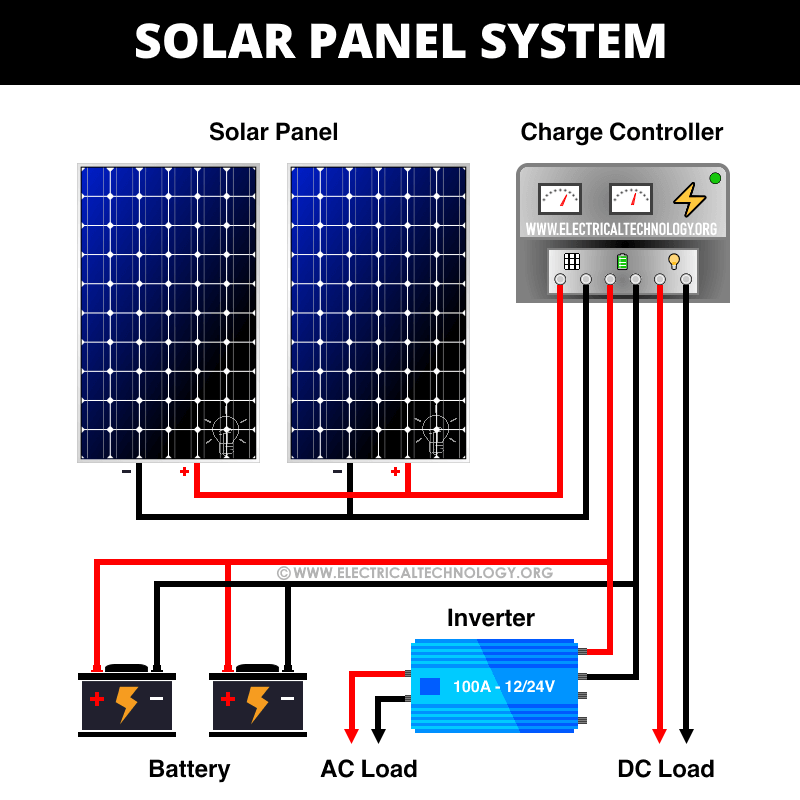

The following basic solar panel installation system shows the important rule of solar charge controller and an inverter. The inverter (which converts DC power from both batteries and solar panels into AC power) is used to connect the AC appliances through charge controller. On the other hand, the DC appliances can be directly connected to the solar charge controller to feed up the DC power to the appliances via PV panels and storage batteries.

A solar street light system is a system that uses a PV module to transform sunlight to DC electricity. The device uses only DC energy and includes a solar charge controller to store DC in the battery compartment to not be visible during daylight or night.

The solar home system uses energy generated from the PV module to supply home appliances or other household appliances. The device includes a solar charge controller to store DC in the battery bank and a suit for use in any environment where the power grid is not available.

The hybrid system consists of various sources of energy to provide full-time emergency power or other purposes. It typically integrates a solar array with other means of generation such as diesel generators and renewable energy sources (wind turbine generator and hydro generator, etc.). It includes a solar charge controller to store DC in a battery bank.

The solar water pumping system is a system that uses solar power to pump water from natural and surface reservoirs for the house, village, water treatment, agriculture, irrigation, livestock, and other applications.

MPPT solar charge controller minimizes the complexity of any system keeping the output of the system high. Additionally, you can use it with more various other energy sources.

Related Posts:

- How to Wire Batteries in Series to a Solar Panel and UPS?

- How to Wire Solar Panels & Batteries in Series-Parallel Connection?

- How to Wire Solar Panels in Series & Batteries in Parallel? 12/24/48V System

- How to Wire Solar Panels in Parallel & Batteries in Series? 24V System

- How to Wire Solar Panel & Batteries in Parallel for 12V System

- How to Wire Solar Panel & Batteries in Series for 24V System

- Solar Power Plant – Types, Components, Layout and Operation

- Batteries in Photovoltaic Systems – Applications & Maintenance