Difference Between AC and DC Motors

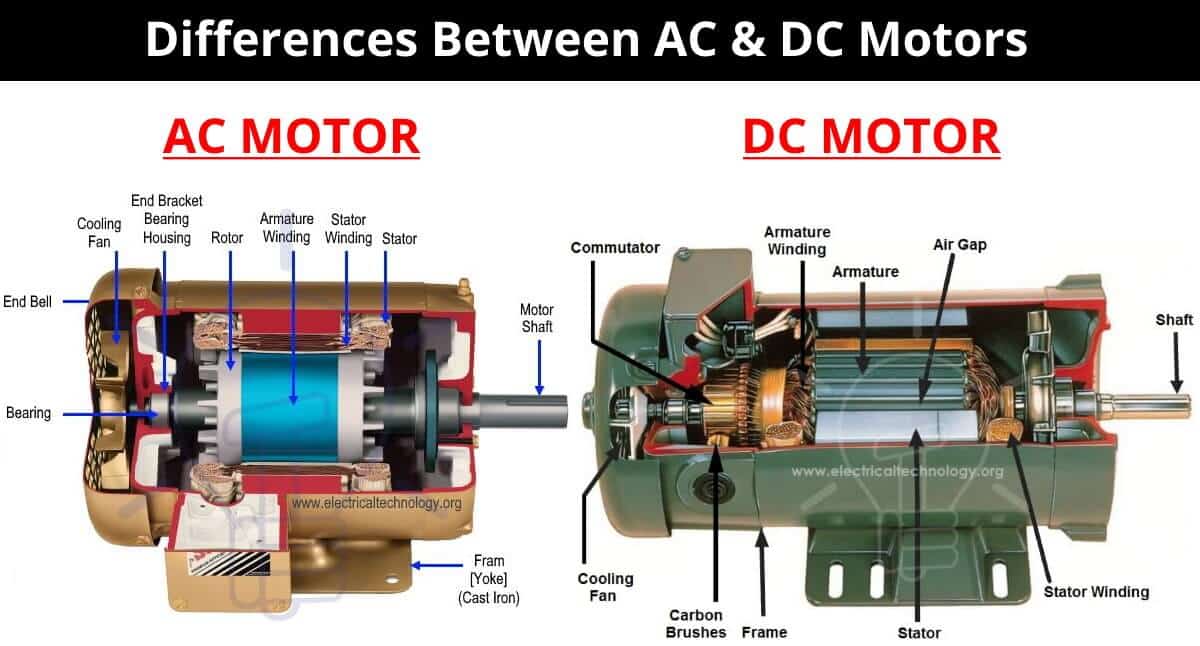

Main Difference Between AC & DC Motor

An electrical machine is a device that converts mechanical energy into electrical energy & vice versa. A motor is a type of electrical machine that converts electrical energy into mechanical energy. These motor can either run on AC electrical energy or DC electrical energy. Therefore, the motors are classified into two main types; AC motor & DC motor.

Both types of motor generate mechanical energy used for moving any mechanical load etc. but their construction, control, efficiency & applications are quite different. You may know more about the basic information about AC and DC Current and Voltage in the previous post.

Before going into the list of differences between AC & DC motor, let’s discuss how a motor works & the basics of AC & DC motor.

What is AC Motor?

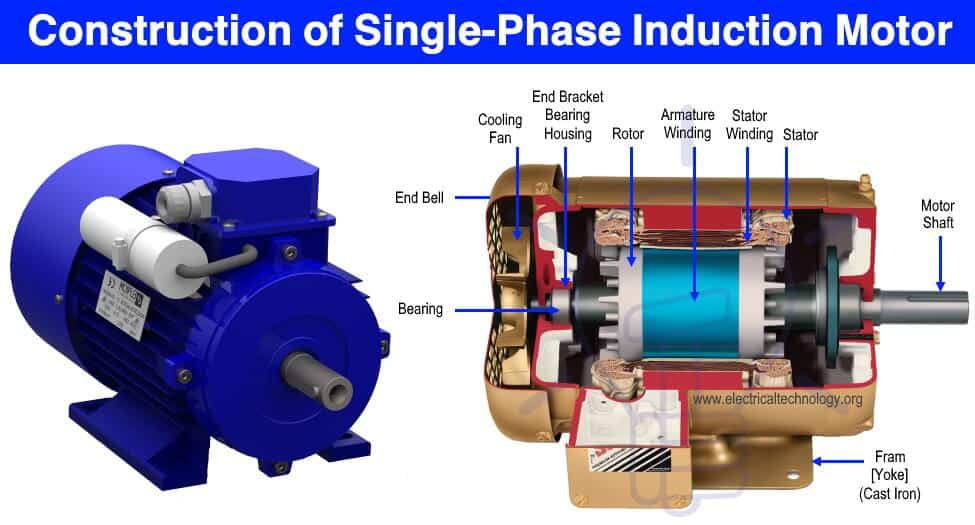

It is a type of electrical machine that converts AC electrical energy into mechanical energy.

There are two types of AC motors; Asynchronous (induction) motor & synchronous motor

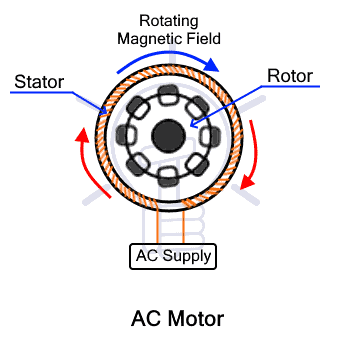

In asynchronous or induction motor, the stator is made of multiple windings, while the rotor (squirrel cage or wound type) is made of closed loops of conductors. The AC is supplied to the stator which generates an alternating flux called a rotational magnetic field.

This magnetic flux generates induced current in the rotor according to faraday’s law of induction. The induced current opposes the magnetic field & starts revolving in its direction. Thus the induction motor either single-phase or 3-phase works on the principle of electromagnetic induction between the stator & rotor.

In a synchronous motor, a separate DC is supplied to the rotor through slip rings to generate its own magnetic field or a permanent magnet is being used. The AC input is supplied to the stator to generate a rotational magnetic field.

The rotor magnetic field gets locked with the stator rotational magnetic field & starts rotating at the exact same speed. Since the rotational magnetic field depends on the supply AC frequency, the speed of the motor only depends on the input frequency. Therefore, it is called a synchronous motor.

Since the input is always applied to the stator, there is no use of carbon brushes. Thus they are more reliable & needs less maintenance. They are more efficient than DC motor in generating greater mechanical power.

But controlling the speed of an AC motor is a little difficult then DC motor. Since it mainly depends on the input frequency, we use a device called VFD (variable frequency drive) to vary the input supply frequency to the motor. They are also called AC motor drives. Their direction is controlled by changing the polarity of only starter winding.

- Related Post: Difference Between AC and DC Generator

What is DC Motor?

It is a type of electrical machine that converts DC electrical energy into mechanical energy.

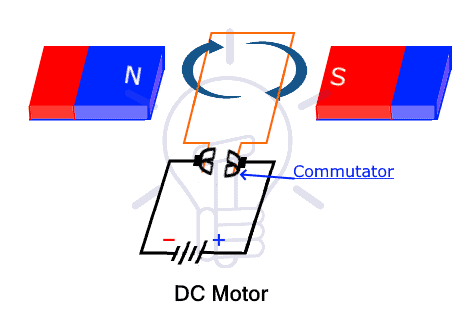

The basic principle on which DC motor operates is “when a current-carrying conductor is placed in a magnetic field, it experiences a mechanical force mutually perpendicular to the magnetic field & current direction”. The direction of the force is determined by Fleming’s left-hand rule.

The armature of the DC motor is made of multiple conductor windings. It is placed inside a housing made for a permanent magnet that generates the magnetic field. The armature carries the direct current supplied by any DC source such as batteries. The magnetic field interacts with the current-carrying conductors of the armature. Thus the armature experiences a mechanical force.

Since the input is applied to a moving part (rotor) of DC motor, we use carbon brushes & commutator to supply alternating current to the armature. Therefore, they are called Brushed DC motor. The brushes & commutator wear out with time, so they need frequent maintenance. The sparks between the commutator also decrease its efficiency & generate noise.

In BLDC (Brushless DC) motor, the stator is made of multiple coils that surround the rotor armature made of permanent magnets. The DC is changed into 3 phase AC using thyristors & supplied to the stator coils to generate a rotating magnetic field. In such motors, the input is applied to the stationary part thus it does not require brushes or commutator. It helps in increasing the performance of the motor as well as its efficiency. You may also know more about stepper motors and servo motors in the previous details posts.

Therefore in DC motor, the input can be applied to the rotor (in brushed DC motor) & as well as the stator (in BLDC motor).

The speed of the DC motor can be easily controlled by varying the input voltage. One simple method of controlling the input voltage is PWM (pulse width modulation). The direction of the DC motor reverses by changing the polarity of the input DC supply. You may also read about the Cable Size Calculation for LT & HT Motors.

- Related Post: Difference Between a Transformer and an Induction Motor

Key Differences Between AC and DC Motor

| AC Motor | DC Motor |

| An electrical machine that converts AC electrical energy into mechanical energy. | An electrical machine that converts DC electrical energy into Mechanical energy. |

| It is powered by alternating current (AC). | It is powered by a unidirectional direct current (DC). |

| There are two main types of AC motors; Asynchronous (Induction) motor & Synchronous motor. | There are two main types of DC motor; Brushed DC motor & Brushless DC (BLDC) motor. |

| AC motors can be single phase (phase and neutral as input) or three phase (3 lines of live wires as input). | DC Motors are single phase having two lines as input (positive and negative). |

| The input supply to the armature is AC, so it does not need commutation. | The input supply is DC, so it needs Commutation the DC input into AC. |

| The armature is always stationary known as Stator. | The armature in brushed DC motor rotates also known as the rotor. |

| The input is supplied to stator thus no need for carbon brushes. | The input is supplied to the rotor thus it needs Carbon brushes & commutator. |

| It does not generate any noise & operate smoothly. | The brushes slide along armature generates noise & sparks. |

| It offers increased output power. | It offers a wide range of speed control. |

| The input supplies can be Single-phase or three-phase. | The input supply is a DC source such as batteries, cell & solar panel, etc. |

| It uses the AC mains as its input supply. | It uses stored backup power from batteries. |

| Its direction can be reversed by changing the polarity of starter winding in a single phase & swapping any two terminals in a 3-phase motor. | Its direction can be easily reversed by changing the polarity of input DC supply. |

| Its speed is controlled by varying the input frequency. It uses VFD for controlling their speed. | It speed is controlled by varying armature current. It is easier to control externally through PWM. |

| It requires less maintenance & is cost-effective. | It requires frequent & costly maintenance. thus they are costlier then AC. |

| The magnetic field rotates while the armature is stationary. | The magnetic field is stationary while the armature rotates. |

| The torque decreases with an increase in speed. | It provides a constant torque over a wide range of speed. |

| AC motor has relatively low efficiency due to the induction current losses. | DC Motor has high efficiency because the magnetic field is generated by a permanent magnet. |

| Not all AC motors are self-starting & require external equipment to start. | All dc motors are self-starting motors. |

| The AC induction motor is the most used electrical motor in the domestic & industrial sectors such as in drill machines, water pumps, fans, washing machines, blowers, etc. | Used in application requiring precise position control & high torque such as lifts, cranes, conveyor belts, etc. also small motors in embedded electronics, small toys. |

The conclusion of this article is that the AC motors are used for their best output power performance, their reliability & the requirement of less maintenance. While the DC motor used because of their easier speed control & direction. But their frequent maintenance is very costly. Overall, using a VFD with an AC motor can provide a less expensive solution to the problem.

Related Posts:

- Difference Between Single Phase & Three Phase Induction Motor

- DC Machine – Construction, Working, Types and Applications

- Speed Control of DC Motor – Voltage, Rheostatic & Flux Control Methods

- Single-Phase Induction Motor – Construction, Working, Types & Applications

- Three-Phase Induction Motor – Construction, Working, Types & Applications

- What is Motor Starter? Types of Motor Starters and Motor Starting Methods

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- Difference between AC Drives and DC Drives

Very nicely explained the subject

Hi ! Just call me roger fron the philippines.can we talk? I need your help maybe you can discourage me to my project.thank you very much if you can reply.

listen to the one that is used for driving a commercial difference of cars and electrical sequences why DC motor use one of those used during the collection of tune-up plugs wires to connect the current driving the voltage in to transformers