Why Do Wind Turbines Have 3 Blades Instead of 2 or 5?

Why are Three Blades Considered Optimal for Wind Turbines, Rather than Two, Four, or More?

Wind turbines have become a cornerstone of renewable energy generation, and their design has evolved through extensive research and development. One notable feature of modern wind turbines is their three-bladed rotor. In today’s post, we will discuss why the 3-blade configuration is a suitable option for wind turbine generators instead of four, five, or more blades.

3 blades are optimal for wind turbines due to a balance between aerodynamic efficiency, mechanical stability, and cost-effectiveness. Aerodynamically, three blades provide sufficient lift and energy capture while minimizing drag and turbulence, which would increase with more blades.

Structurally, 3-blades distribute the mechanical load evenly, reducing stress and wear on the turbine components. Economically, fewer blades mean lower manufacturing, transportation, and maintenance costs. Thus, the three-blade design is a practical compromise that maximizes energy production while maintaining structural integrity and cost efficiency.

The choice of three blades, rather than four or five, is based on a combination of aerodynamic efficiency, structural considerations, and economic factors. This article explores these reasons in detail, providing electrical engineering students with a comprehensive understanding of the engineering principles behind the three-bladed wind turbine design.

Aerodynamic Efficiency

- Optimal Rotor Efficiency:

- The primary goal of wind turbine design is to maximize energy capture from the wind. The Betz Limit, a fundamental principle in wind energy, states that no wind turbine can capture more than 59.3% of the kinetic energy in the wind.

- Three blades strike a balance between capturing a significant amount of wind energy while minimizing drag and turbulence. More blades can increase aerodynamic drag, leading to a decrease in overall efficiency.

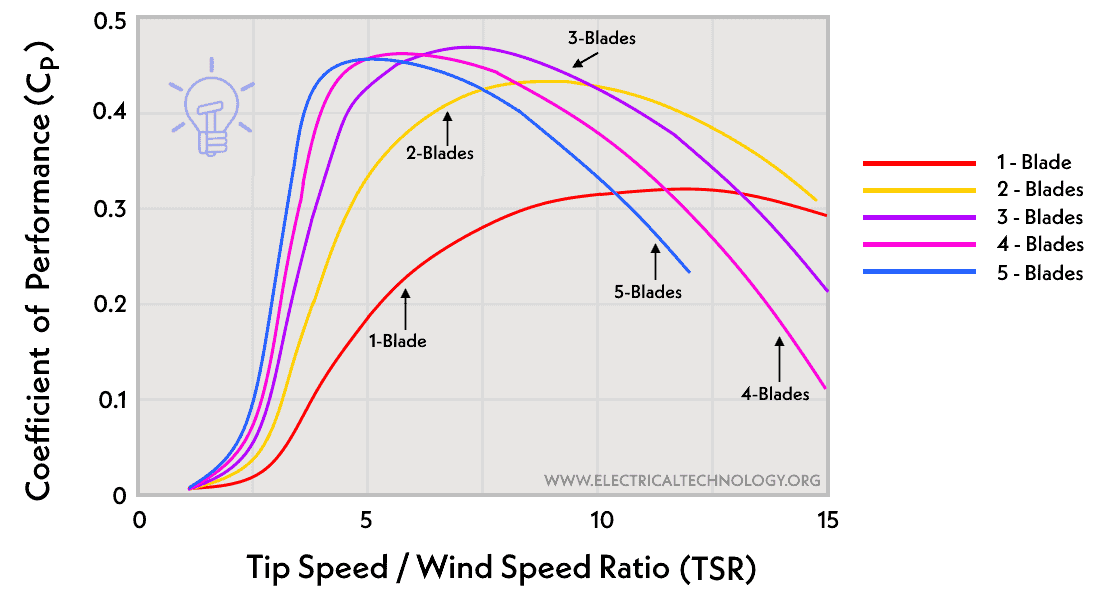

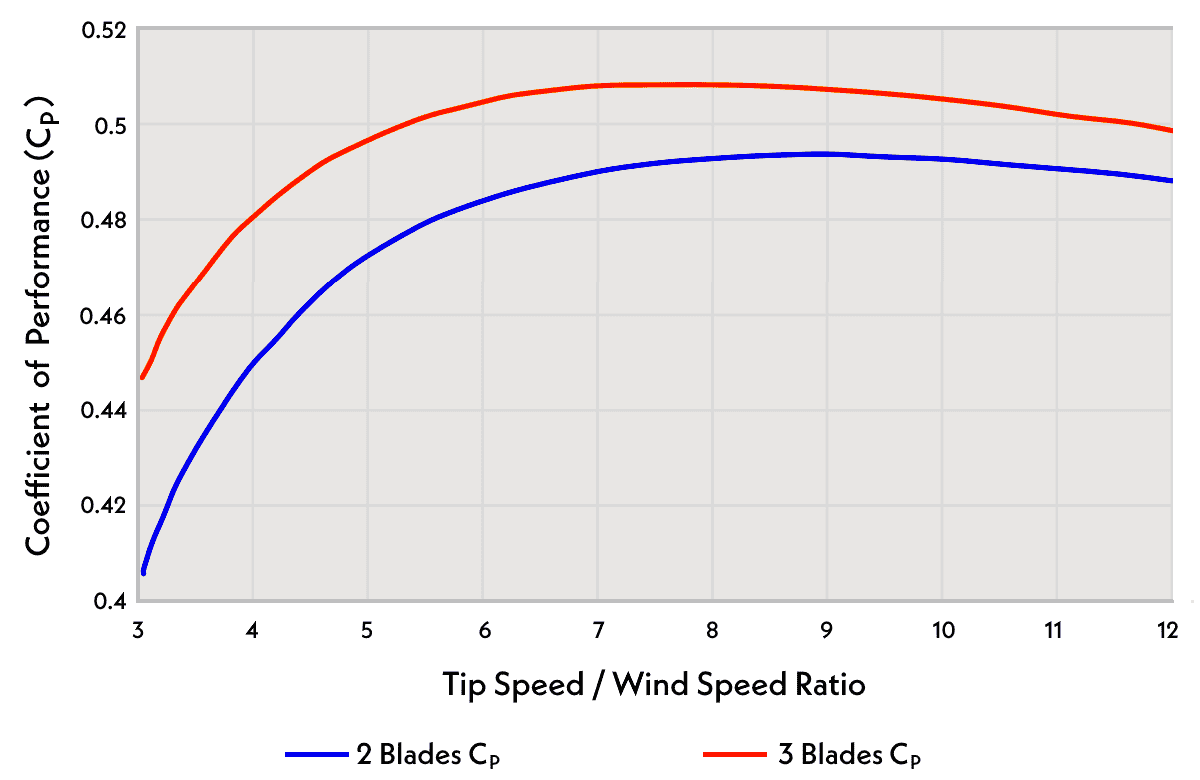

- Tip Speed Ratio:

- The tip speed ratio (TSR) is the ratio of the speed of the blade tips to the wind speed. For optimal power generation, wind turbines must operate at an optimal TSR, which varies depending on the number of blades.

- A three-bladed rotor achieves an optimal TSR that balances rotational speed and energy capture. This optimal TSR is typically around 6 to 8 for three-bladed turbines, providing an efficient compromise between aerodynamic performance and mechanical stress.

Structural Considerations

- Mechanical Load and Stress:

- The mechanical load on turbine blades increases with the number of blades, leading to higher stresses and potential structural issues. With 3 blades, the load is distributed evenly, reducing mechanical stress and wear on the blades and hub.

- Fewer blades also mean less mass at the rotor, leading to lower centrifugal forces and reduced fatigue on the turbine components.

- Dynamic Stability:

- Three-bladed turbines offer better dynamic stability compared to turbines with more blades. The symmetry of a three-bladed design ensures balanced rotational forces, minimizing vibrations and enhancing the longevity of the turbine structure.

Economic Factors

- Manufacturing and Maintenance Costs:

- Manufacturing blades for wind turbines is a complex and costly process. Increasing the number of blades from three to four or five significantly raises production costs.

- Maintenance costs also rise with more blades due to the increased complexity of the rotor and the need for more frequent inspections and repairs. Three blades offer a practical compromise between performance and cost-effectiveness.

- Transportation and Installation:

- Transporting and installing wind turbine blades is a logistical challenge. 3 blades strike a balance between size, weight, and ease of transportation, making them more practical for large-scale wind farms.

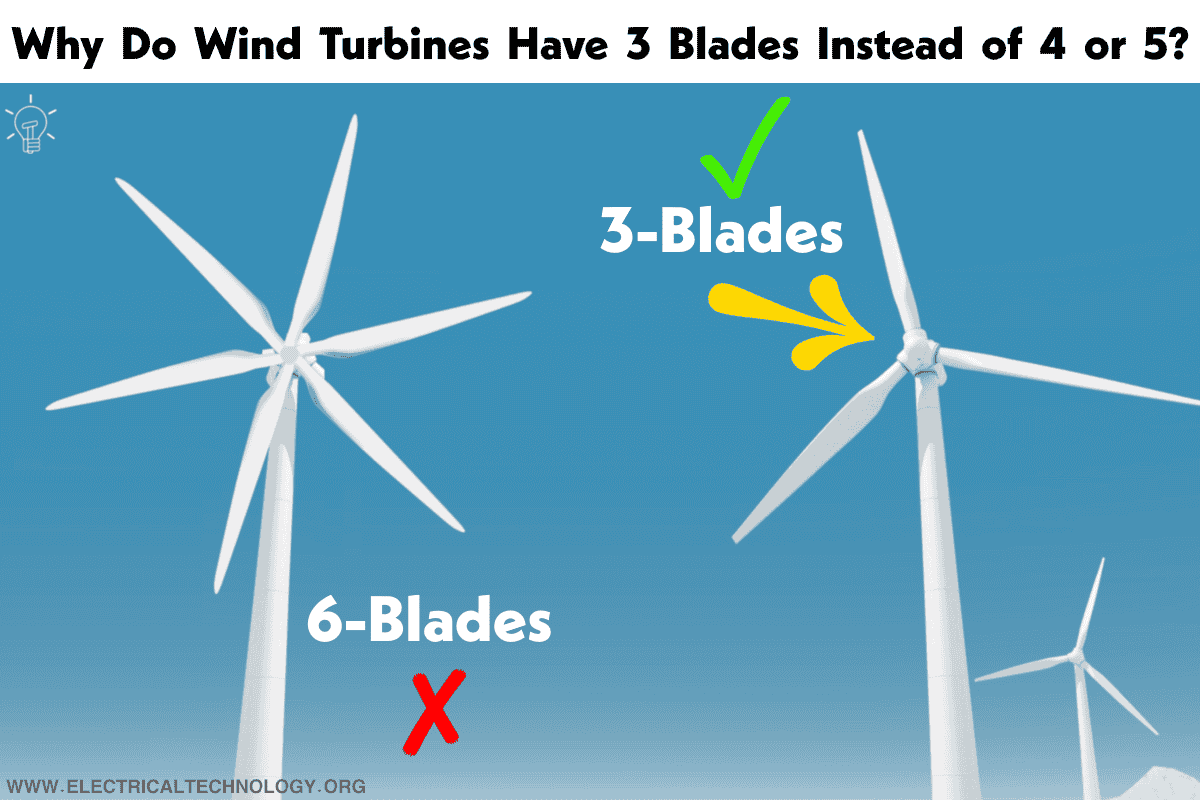

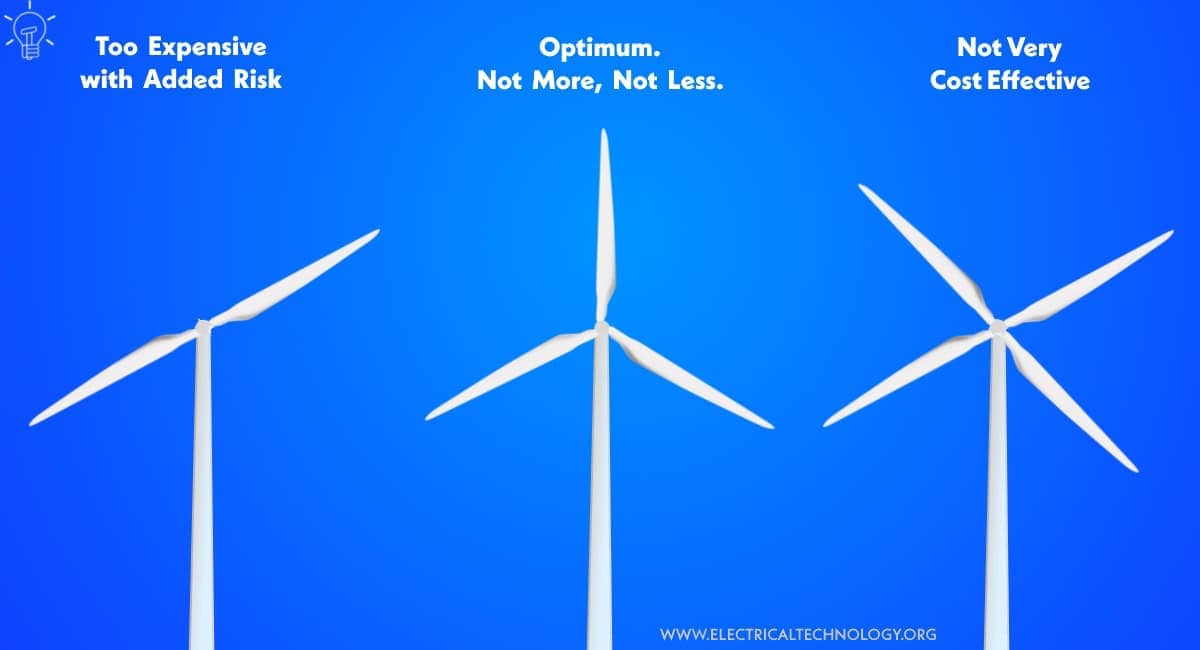

The following fig shows the comparison between 2, 3 and 4 bladed windmill turbine generators.

Why Only Three Blades Instead of Two, Four, or More?

The three-bladed design of modern wind turbines is a result of careful consideration of aerodynamic efficiency, structural integrity, and economic viability. While adding more blades might offer some advantages for small-scale turbines at low speeds, the benefits diminish at high speeds due to increased drag and lower optimal TSRs.

Wind turbines are designed with three blades instead of four or five primarily for aerodynamic efficiency, structural integrity, and cost-effectiveness. Aerodynamically, 3 blades strike a balance between capturing wind energy effectively and minimizing drag.

This configuration allows for optimal energy conversion without excessive aerodynamic losses that could occur with more blades. Structurally, distributing the load among three blades reduces stress and ensures mechanical stability, enhancing the turbine’s longevity and reliability.

Economically, fewer blades mean lower manufacturing and maintenance costs, making three-bladed turbines more viable for large-scale deployment. In essence, the three-blade design represents a well-engineered compromise that maximizes performance while minimizing operational expenses.

While it is known that four blades will produce more power compared to two or three blades, the blade size and rotation speed need to be increased in a two-blade turbine to achieve the same power.

Alternatively, a two-blade design could be transformed into a four-blade design, but this introduces complications such as higher initial costs, noise, and the need for custom rotors and structures. That’s why manufacturers opt for a three-blade design instead of fewer or more blades in large-scale turbines.

In short, the three-blade design is optimal compared to two or four blades because of its stability, light weight, high efficiency, energy output, structural durability, and lower cost.

If Fewer Blades are More Economical, Then Why Use 3 Blades? Why Not 2 Blades?

If we want to use two blades instead of three for the same output power, we will need to increase the blade size by 50%.

If that is not an option, we will have to increase the rotation speed of the two-bladed turbine by 22.5% to achieve the same power as a three-bladed turbine.

However, increasing the speed will result in loud noise, which is not suitable, especially in residential areas.

If we increase both the speed and blade size, it will put extra stress on the central rotor and structure because the centrifugal force will increase the apparent weight of the blades. This will lead to additional costs as the structure and rotor will need to be redesigned according to new specifications and requirements.

Will Adding More Blades to the Turbine Increase Efficiency?

The question of whether adding more blades to a small-scale turbine operating at high speeds can increase efficiency is an intriguing one. While large-scale turbines benefit from three blades, small-scale turbines have different dynamics that can influence their design.

- Blade Number and Efficiency:

- For small-scale turbines, adding more blades can improve efficiency at low wind speeds by increasing the surface area for capturing wind energy. However, at high speeds, the benefits diminish due to increased aerodynamic drag and reduced rotational speed.

- Tip Speed Ratio and Small-Scale Turbines:

- Small-scale turbines typically operate at higher TSRs compared to large turbines. Adding more blades can lower the optimal TSR, potentially leading to suboptimal performance at high speeds. Thus, while more blades might capture more energy at low speeds, they can hinder performance at high speeds.

- Structural and Economic Trade-offs:

- Similar to large-scale turbines, small-scale turbines with more blades face higher mechanical loads and increased manufacturing and maintenance costs. These trade-offs must be carefully considered to determine if the marginal gains in efficiency justify the added complexity and expense.

Studies prove that a five-blade wind turbine offers better annual performance (up to 60%) compared to a three-blade wind turbine, especially in areas with an average wind speed of 5 meters per second. In low wind speed conditions, the five-blade design is more suitable as it overcomes high-speed malfunctions, reduces noise, and looks more aesthetic compared to the traditional three-blade wind turbine design.

The following fig shows the performance of 1, 2, 3, 4 and 5 blades wind turbines.

For these reasons, adding more blades would increase the weight and require a custom structure and rotor, raising the initial cost while the output would still be lower than with three blades. Therefore, adding an extra blade to a large-scale wind turbine is not a suitable option.

Related Posts:

- Why 3-Phase Power? Why Not 6, 12 or More for Power Transmission?

- Which Type of Solar Panel is Best: P Type or N Type, and Why?

- Why is a Capacitor Needed for a Single-Phase Motor?

- Why is the Grounding Wire Bare and Not Insulated?

- Why are there Small Red Lights Around the CCTV Cameras?

- Why is the Standard Frequency 60 Hz in the US & 50 Hz in the EU?

- Why Do Prongs in Electrical Plugs Have Holes in Them?

- What are the Tiny Cylinder in Power Cords & Cables?

- Why Earth Pin is Thicker and Longer in a 3-Pin Plug?

- Why Don’t Birds and Squirrels Get Electrocuted on Power Lines?

- What are the Colored Aerial Marker Balls on Power Lines For?

- What Happens if a Battery is Connected to the AC Supply?

- Is Lightning AC or DC ?