Types of Control & Communication Cables

Types of Cables used in Control & Communication

Control Cables

Control cables are used to connect instrument transformers, coils of circuit breakers and contactors, control switches, meters, protection devices and other control and monitoring equipment.

Control cables have conductors in copper, insulation and outer sheath in PVC and they may have up to 150 cores.

Each core is identified by a different color or by a number marked on the insulation.

In order to avoid electromagnetic interference caused by power cables laid nearby control cables may be shielded.

Communication Cables

Communication cables are used for the transmission of data, voice and images, like CCTV systems.

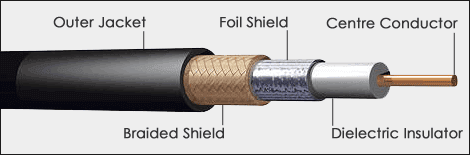

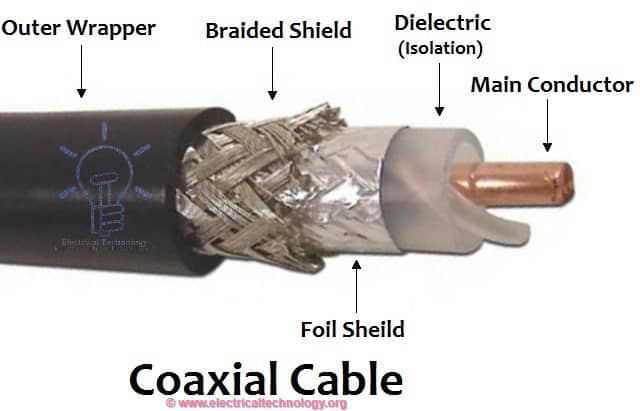

The first type of cables used for these functions were coaxial cables.

Coaxial cables have an inner conductor surrounded by a tubular insulating layer, surrounded by a tubular conducting shield, like is shown in Figure 2.

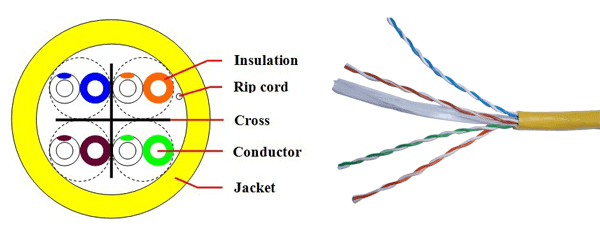

Modern technology calls for the use of cables with copper conductors organized in twisted pairs, with insulation and outer sheath of polyurethane.

Common types are:

- UTP (unshielded twisted pairs) – the most used.

- STP (shielded twisted pairs).

- FTP (foiled twisted pairs).

This type of cables is usually manufactured with twisted pairs, each conductor with an overall diameter of 0.5 mm (the designation of the cable is: UTP / STP / FTP N x 2 x 0.5, “N” being the number of pairs), and they are used when the length is lower than 100 m.

This type of communications cables are classified in categories (Cat) according to the performance for crosstalk and “system noise”.

Categories are defined in accordance with IEEE (Institute of Electrical and Electronic Engineers) standards and EIA / TIA Standard 568B (EIA: Electronic Industries Alliance – USA; TIA: Telecommunications Industry Association – USA).

Nowadays the most recent category is Cat 6 which provides performance of up to 250 MHz and is suitable for 10BASE-T10, 100BASE-TX (Fast Ethernet), 1000BASE-T/1000BASE-TX1 (Gigabit Ethernet) and 10GBASE-T10 (10-Gigabit Ethernet).

Each pair is identified by a color and the conductors of each pair are identified having an insulation of the same color of the pair and an insulation of the same color of the pair and white, as shown in Figure 3.

Also Read: Cables Feeder Protection & Faults Types, Causes & Differential Protection

When distances are longer than 100 m an optical fiber cable must be used.

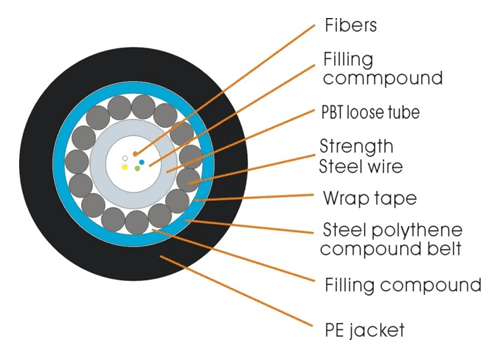

An optical fiber cable contains one or more optical fiber.

The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable will be deployed.

An example may be seen in Figure 4.

Also Read: Submarine Cables – Construction, Characteristics, Cables Laying & Joints

Optical fiber consists of a core and a cladding layer; the cladding is usually coated with a layer of acrylate polymer or polyimide, for the protection of the fiber from damage.

Modern cables come in a wide variety of sheathings and armor, designed for applications such as direct burial in trenches, dual use as power lines (carries data on a conductor that is also used simultaneously for AC power transmission or distribution), process known as PLC (Power Line Carrier), installation in conduit, lashing to aerial telephone poles, submarine installation and insertion in paved streets.

In electrical transmission and distribution networks optical fiber cables are used for the communication between Control Centres and protection systems.

Splicing, joining and termination of twisted pair cables and optical fiber cables require trained, specialized and certified personnel.

Also read: Ferrite Bead: Tiny Cylinder in Power Cords & Cable. Why?