Transformers Fire Protection System – Causes, Types & Requirements

Basic Requirements for Transformers Fire Protection System

Causes of Fire in Transformers

Excessive overheating, extremely severe short circuits, faults in the oil and lightning strokes may cause a fire on transformers.

Transformer fires are rare but the impact is great. Even though a transformer involved in a fire likely will be destroyed almost immediately, as seen in the figure below, the fire’s effect on adjacent equipment and structures can be mitigated and therefore must be considered.

An uncontained fire can do a significant amount of damage and result in a prolonged and unscheduled outage.

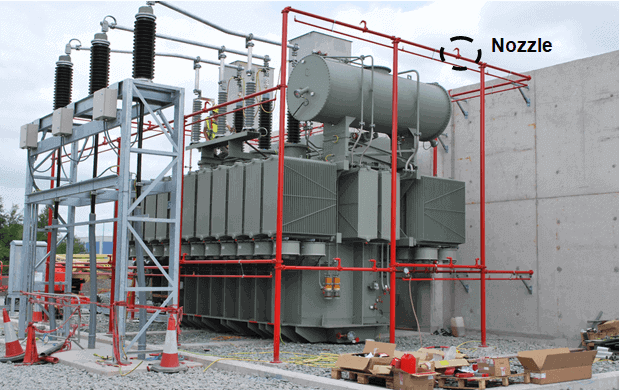

For transformers of high rated power and voltages above 123 kV is usual to provide a fire protection system, using water spray fixed systems, commonly called transformer “deluge” or “fire water” systems, as shown in Figure 1

Figure 1 – Transformer fire protection system

Related Posts:

- What will happen if the primary of a transformer is connected to DC supply?

- Uses and Application of Transformer

This system is activated through flame detectors if the transformer is installed outdoors, or by smoke detectors, if the transformer is installed indoors.

Types of Fire Protection System of a Transformer

Fire protection system of a transformer may be divided into:

- Water Based and Mist Systems: fire pumps; water spray fixed system/nozzles; valves; valves components; piping.

- Fire Detection System: fire detectors; control panel; cabling.

Related Posts:

- Can we operate a 60HZ Transformer on 50Hz Supply Source and Vice Versa?

- TRANSFORMER NAMEPLATE (GENERAL REQUIREMENTS).

Fire suppression requirement may be mitigated when the transformer is located remotely from the structure and other equipment, or the burning oil can be contained.

Protection of the plant structure and adjacent equipment, as well as reducing hazards to personnel, warrants fire suppression in most cases.

In some cases, use of less-flammable insulating fluids may mitigate the need for fire suppression and should be considered as an alternative.

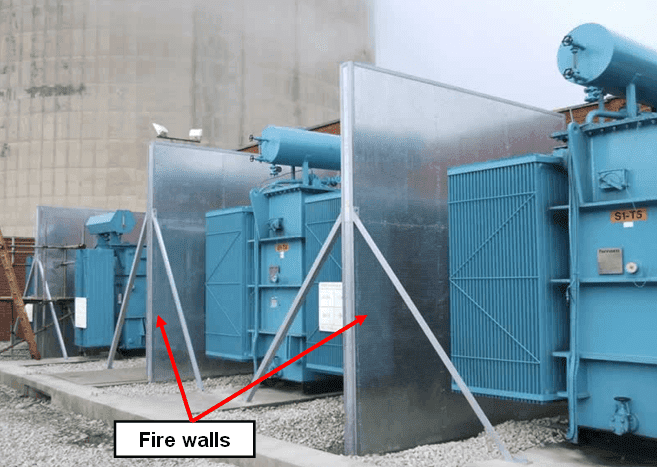

In common practice that industry standards and insurance requirements include fire suppression and fire walls (Figure 2) for transformers containing as little as about 1,900 l of combustible oil where acceptable separation/barriers from buildings and other equipment cannot be achieved.

Related posts:

- A (50/60 Hz) Transformer. Which one will give more Output? (When operates on 50 or 60 Hz frequency)

- Transformers MCQs With Explanatory Answers

Figure 2 – Fire walls

Related Posts:

- Transformer Efficiency, All day Efficiency & Condition for Maximum Efficiency

- What is the difference between Power Transformers and Distribution Transformers?

Requirements for Transformer Fire Protection

Summarizing, the basic principles are:

- New facilities with large, mineral-oil-filled transformers located near the plant structure or other equipment should include active transformer fire suppression systems to protect the structure and adjacent equipment and properly designed containment systems to protect the environment.

- For new facilities, and where justified at existing plants, serious consideration should be given to locating mineral-oil-filled transformers away from the plant, other equipment, and waterways as a way of reducing fire and environmental risks. In these cases, active fire suppression may not be necessary if other considerations allow.

- Existing, functional fire suppression systems should continue to be used to protect plant structure and other equipment but should be reviewed for adequacy and compliance with current codes and standards.

- Inactive fire suppression systems should be reviewed for adequacy and compliance with current codes and standards and restored to service.

- Fire suppression systems should be added to existing facilities (where none currently exist) and where required to protect the plant structure or other equipment.

- Transformers should have periodic condition assessments in addition to routine inspection, testing, and maintenance. Transformers with low condition indices should be programmed for rehabilitation or replacement.

- Fire walls between adjacent transformers, between transformers and the plant structure, between single-phase transformers, or between transformers and other equipment should be added where feasible and appropriate to contain a fire and explosion, thus reducing collateral damage.

- Fire suppression systems must be adequately operated, maintained, and tested.

- Containment and oil-water separation structures must comply with all applicable laws, regulations, and standards.

- Access to transformers will be limited only to those having official business in the area. Proximity of the public to transformers will be restricted.

- Applicable environmental laws must be accommodated.

Related Posts:

Download Project Report on Transformer Fire Protection

Related Posts:

- Power Transformer Protection & Faults

- Power Transformers Maintenance, Diagnostic & Monitoring

- Motor Protection – Types of Faults and Protection Devices

- Cables Feeder Protection – Faults Types, Causes & Differential Protection

- Overhead Lines Faults & Protection

- How To Locate Faults In Cables? Cable Faults, Types & Causes

- Fault Current Limiter and Their Types

- GFCI: Ground Fault Circuit Interrupter. Types, Working & Applications

- All About Electrical Protection Systems, Devices And Units

220kv sf6 breaker operation and maintenance procedures required.