What is a Thermistor? Types of Thermistors and Applications

Thermistor, Types, Working, Advantages, Disadvantages and Applications

Temperature plays a vital role in the operation of any electronic circuit. Each electronic component has its thermal limit and safe operating temperature range that needs to be maintained for smooth and precise operation. To monitor the temperature, various sensors are used where a thermistor is an efficient and cost-effective solution.

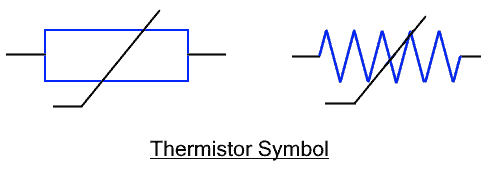

What is a Thermistor?

The word “Thermistor” is a combination of the words “Thermal” and “resistor“. A thermistor is a type of resistor whose resistance changes with the change in temperature. It is a passive component that does not require an extra power source to operate. They are inexpensive and accurate in measuring temperature. But they do not operate well in extreme conditions such as very high or very low temperatures.

Each and every resistor’s resistance is affected by the change in temperature but its temperature coefficient is so low that the changes in its electrical properties are not that significant. On the other hand, thermistors having very high thermal coefficients are prone to significant electrical changes with temperature.

Working Principle

The thermistor is used for measuring temperature. The working principle behind the temperature measurement is its resistance.

A thermistor is made of semiconductor material whose resistance greatly depends on the surrounding temperature. They significantly vary with the temperature. Depending on the material used, the resistance may either increase or decrease with an increase in temperature called the PTC and NTC thermistor.

This change in resistance can be calibrated and measured to calculate the exact temperature of the environment in a circuit.

For accurate measurement, It is necessary to have maximum surface contact with the component or equipment. To maximize the thermal conductivity between the surfaces, special thermal paste is used between them.

Types of Thermistor

There are two types of thermistors

- PTC (Positive Temperature Coefficient) Thermistor

- NTC (Negative Temperature Coefficient) Thermistor

To understand the basic difference between PTC and NTC thermistors we can use this linear equation for the relation between the change in temperature and resistance.

dR = k dT

Where

- dR = Change in resistance

- k = Temperature Coefficient

- dT = Change in Temperature

The temperature coefficient can be either positive or negative and it completely changes the electrical property of the component. A thermistor having a positive coefficient is called PTC while a negative coefficient thermistor is called NTC.

PTC Thermistor

PTC or Positive Temperature Coefficient thermistor is a type of thermistor whose resistance is directly proportional to the surrounding temperature. Its resistance increases with an increase in the temperature and decreases with a decrease in the temperature.

It is made of polycrystalline ceramic material. Its resistance increases non-linearly in a curve. The increase in resistance is very small at low temperatures which increases rapidly when the temperature reaches above the switching point (TR).

The given symbol represents a PTC thermistor with (T+) to show the thermistor has a positive temperature coefficient.

Characteristic Curve

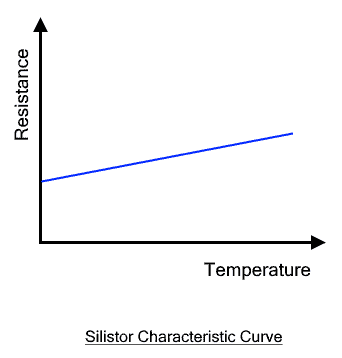

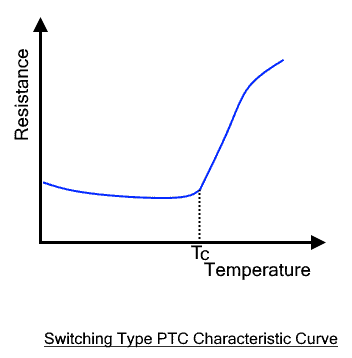

The characteristic curve of a thermistor shows the relation between the resistance (dependent – displayed on Y-axis) and the temperature (Independent – displayed on X-axis). Here is the characteristics curve of a PTC thermistor.

Thermistors have rated resistance taken at 25° C. therefore, any PTC thermistors having a rated resistance is its resistance at 25° C.

Types of PTC Thermistor

There are two types of PTC thermistors

Silistors

The silistor is a PTC thermistor made from silicon having the linear characteristic. The resistance increases linearly with the increase in the temperature.

Switching Type PTC

The switching type PTC is a non-linear thermistor. It is made of a poly-crystalline ceramic body. It has a small NTC region where the resistance decreases a little with an increase in temperature up to a certain point called critical temperature or the curie temperature. After that point, the resistance increases exponentially with a slight increase in temperature.

Advantages of PTC Thermistor

Here are some advantages of PTC thermistor

- It provides better protection against overloading

- It can efficiently and safely start an electrical motor.

- Its resistance varies linearly with temperature.

- It is compact in size.

- It is cheaper

Disadvantages of PTC Thermistor

Here are some disadvantages of PTC thermistors.

- They are not very sensitive to as compared NTC thermistors.

- Its reading is affected by the self-heating effect.

- It has a limited temperature range as compared to the NTC thermistor.

Related Post: LVDT: Linear Variable Differential Transformer and Inductive Sensors

PTC Applications

Here are some applications of PTC thermistors.

- Over-Current Protection: When the current exceeds a certain limit, it generates heat that can damage the wiring as well as the components. The resistance of the PTC thermistor increases with the temperature that can be used to prevent the current from increasing.

- Inrush Current Protection: Inrush current is the starting current drawn by a motor during its startup that is very high and it can damage its windings. A PTC thermistor heats up and its resistance increases that limits the inrush current.

- Motor Starting: Some motors include an auxiliary startup winding that is only used for starting the motor. Initially, the PTC resistance is very low and it allows the current to pass through this auxiliary winding. The temperature gradually increases as well as the PTC resistance. Once the motor attains certain speed, the PTC resistance increases to a point that blocks the current flow to the startup windings.

- Time Delay: The PTC can switch from a low resistance state to a high resistance state after some time delay. The time can depend on the change in temperature or the voltage in use. It can be used in circuits to achieve a calculated time delay function such as in circuit breakers, timers, relays.

- Temperature Control: The PTC thermistor can control a heater to maintain a temperature from raising a certain limit. The PTC breaks the supply when the temperature exceeds certain limits and switches back on when the temperature falls below a certain limit.

- Electrical Fuse: The resistance can also increase with an increase in its internal temperature due to the current flowing through it. It can act as a fuse to stop the current flow in case of over current.

Related Post: Capacitive Sensor and Transducer and Its Applications

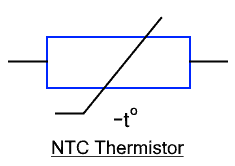

NTC Thermistor

As its name suggests, NTC or Negative temperature coefficient thermistor has a negative coefficient k. therefore, its resistance varies inversely with the temperature. The resistance decreases with an increase in temperature and vice versa. Here is the symbol of the NTC thermistor.

NTC thermistors are made of oxides of nickel, cobalt, copper, iron and titanium. They usually operate at a very large range of temperature with very precise temperature monitoring.

They are mostly used in temperature sensing devices as opposed to PTC that are mostly used as current limiters.

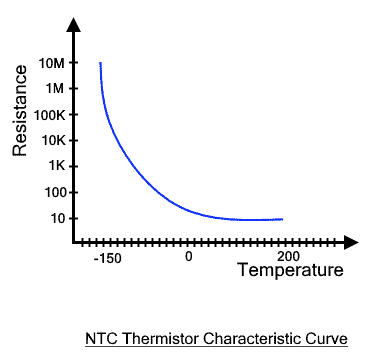

Characteristics Curve

The following characteristic curve shows the comparison between the resistance and temperature of the NTC thermistor. The resistance varies non-linearly with the temperature change in a form of a curve.

The given graph shows a drastic change in the resistance from a few ohms to mega ohms with a change in temperature thus offering precise temperature sensing and high sensitivity.

Advantages of NTC Thermistor

Here are some advantages of NTC thermistor

- They are far more sensitive than PTC.

- It operates at a wider range of temperatures.

- It has a quicker response time with high accuracy.

- They provide a precise temperature reading.

- They are compact and take less space on a circuit board.

Disadvantages of NTC Thermistor

Here are some advantages of NTC thermistor

- The self-heating effect can cause errors in temperature measurement.

- The resistance varies non-linearly with the temperature.

NTC Applications

The NTC thermistor is mainly used for measuring the temperature. Here are some of the applications of NTC thermistors:

- Digital Thermometer: NTC resistance significantly changes with a small change in temperature and it can sense a wide range of temperatures with high accuracy. This is why NTC thermistor is used in a digital thermometer.

- Temperature Monitoring and Control: the operation of electronic components especially semiconductor based components greatly depends on the ambient temperature. The NTC thermistors are used for monitoring and maintaining temperature to ensure uninterrupted operation of the equipment.

- Fire Alarm: Fire alarms are used in every building to detect the first sign of fire and alert the personnel inside the building as well as the concerned authorities. NTC thermistors are used in fire alarms to sense the temperature.

- Inrush current protection: The inrush current is a very high motor starting current. The NTC thermistor offers high initial resistance that limits the starting current. it is far more effective than using a fixed resistor for limiting the inrush current.

Types of Thermistor based on Material

The thermistor can be shaped into three different types. Therefore, they are divided into the following types:

- Bead Thermistor

- Disc and Chip Style thermistor

- Cylindrical Thermistor

- Metalized surface thermistor

Bead Thermistor

As the name suggests, bead thermistors are manufactured in the shape of a bead. It is made of connecting the wire directly to the ceramic body. They offer better stability with a quick response time. Their structure allows it to operate at very high temperatures. To further protect it from mechanical damage, they are encapsulated in glass. They are the smallest in size which is why they have the quickest response time. But they have low current handling capabilities.

Disc and Chip Style Thermistors

The body of such a thermistor is shaped in the form of a disc or chip. It has a larger metal surface. Due to its larger surface, they have a slower response time and have higher current handling capabilities than the bead type.

Cylindrical Thermistor

Such thermistor’s body is pressed into a cylindrical shape. They have a larger size as compared to other types. They are robust and reliable.

Metalized Surface Thermistor

Such thermistors have metalized surface contacts instead of sintered lead wire as in the other mentioned types. They have radial or axial metal contacts that are used for directly connected or surface-mounting on a circuit board.

The thermistors are also divided based on the materials used. They improve their performance, durability and stability.

Glass Encapsulated Thermistors

The thermistors are sealed in a glass body to improve their operating temperature range. It is an air-tight glass body that improves its stability and protects it from mechanical damage. Glass encapsulated thermistors can operate at above 150° C.

PAN Thermistor

The PAN thermistor is made from a special type of metal oxide that is extremely sensitive to temperature. It has very high accuracy with a tolerance up to ±0.2°C. It has a very quick response time with great precision.

It is a type of NTC thermistor used in industries for its accurate measurement. It has an operating range of 25° to 85° C.

Precision Interchangeable Thermistors

They are the most precise thermistor manufactured based on a specific characteristics curve. They are fast and have long-term stability with high-temperature accuracy. They offer interchangeability over the range of 0°C to 70°C. They do not require individual calibration.

Advantages and Disadvantages of Thermistors

Advantages

Here are some advantages of thermistor

- It has a quick response time

- It has a higher degree of accuracy and high precision.

- They operate at a wide range of temperatures especially NTC thermistors.

- They are far more stable in long-term use.

- It can be designed to withstand any mechanical stress

- It can be designed in any shape.

- It has higher sensitivity than other temperature sensors.

- It has a smaller size.

- They have robust designs.

- It is cheaper than other sensors.

- It can be used in remote locations.

Disadvantages

Here are some disadvantages of thermistor

- Most thermistors have a limited temperature range especially precision thermistors having high accuracy.

- The resistance varies non-linearly with respect to temperature.

- Due to the self-heating effect, error may get induced in the reading.

- They are fragile

Applications of Thermistor

Here are some applications of thermistor

- The main function of a thermistor is to be used as a temperature sensor.

- They are used in digital thermometers.

- Thermistors are used to control and maintain the temperature of a room for domestic and office use.

- They are used in automobiles to monitor the temperature.

- They are used for protection against overcurrent in electrical circuits and also act as a fuse.

- The Inrush thermistors are used for the safe starting of electrical motor.

- They also provide time delays in an electrical circuits.

Related Posts:

- Thermocouple – Types, Construction, Working and Applications

- RTD – Resistance Temperature Detector: Construction, Types, Working & Applications

- Resistor Symbols – Variable, Adjustable and Special Resistors Symbols

- Resistor Color Code Calculator – 3, 4, 5 and 6 Band Resistors Calculation

- SMD Resistor Codes: How to Find the Value of SMD Resistors

- Infrared Motion Detector Circuit – Diagram, Working and Applications

- Rain Alarm Sensor– Snow, Water and Rain Detector Project

- Simple Touch Sensitive Switch Circuit using 555 Timer and BC547 Transistor

- Automatic Bathroom Light Switch Circuit Diagram and Operation

- Internet of Things (IoT) and Its Applications in Electrical Power Industry