Why Do DC Motors Have Higher Starting Torque than AC Motors?

Why is the Starting Torque of a DC Motor Greater Than That of an AC Motor?

DC (direct current) motors generally have higher starting torque compared to AC (alternating current) motors. The starting torque of a motor is crucial for applications where the load initially resists motion, such as in conveyors, crushers, and other heavy-duty machinery.

In a DC motor, the torque is produced by the interaction of magnetic fields generated by the stator (field winding) and the rotor (armature winding). The direction of the current in the armature winding is controlled by a commutator, which ensures that the torque-producing magnetic field is always in the same direction relative to the rotor. This design allows for a smooth and consistent torque production throughout the rotation of the motor.

The starting torque of DC shunt motor is given by:

The starting torque of a DC machine can be adjusted and controlled easily by varying the armature voltage or by using additional external resistors. This flexibility in controlling the starting torque makes DC motors suitable for applications that require a high torque at startup.

In applications where high starting torque and precise speed control are needed, DC motors are preferred, such as in vehicles, cranes, elevators, winches, crushers, CNC and conveyor systems, material handling/lifting equipment, traction control, etc.

On the other hand, AC motors, especially induction motors, rely on the induction of a magnetic field in the rotor by the stator’s rotating magnetic field. During the startup of an AC motor, there is a brief period when the rotor speed is not synchronized with the rotating magnetic field, resulting in lower torque at startup. This is known as “slip,” and it can affect the starting torque of AC motors.

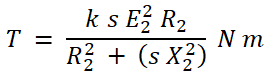

The starting torque of AC induction motor:

For this reason, AC motors, especially induction motors, may have lower starting torque compared to DC motors. However, some AC motors, such as synchronous motors, can provide higher starting torque under specific conditions.

In applications where low starting torque and precise control are needed, AC motors are preferred to be used, such as in pumps and compressors, fans, washing machines, refrigerators, air conditioners, and vacuum cleaners; HVAC systems; cranes, elevators, and escalators; winches; printing and textile machinery; CNC and conveyor systems; material handling/lifting equipment; traction control, etc.

While advancements like variable frequency drives (VFDs) have improved the control and performance of AC motors, DC motors still offer certain advantages in terms of controllability and starting torque. The ability to control the direction and magnitude of the current in the armature winding of a DC motor allows for precise torque control, making DC motors suitable for applications where high starting torque is essential.

Related Posts:

- Why is the Synchronous Motor Not Self Starting?

- How to Run a Three-Phase Induction Motor on a Single-Phase Power Supply?

- What happens if You Connect a 3-Φ Induction Motor to 1-Phase Supply?

- What happens to the 3-Phase Motor When 1 Out of 3 Phases is Lost?

- What happens to the 3-Phase Motor When 2 Out of 3 Phases are Lost?

- Difference between Synchronous and Asynchronous Motor

- Difference Between Brushed and Brushless Motor

- Difference Between Single Phase & Three Phase Induction Motor

- Difference Between AC and DC Motors

- Difference between AC Drives and DC Drives

- What is the Role of Capacitor in a Ceiling Fan?

- Applications of Electric Motors