Difference between AC Drives and DC Drives

Main Differences between AC and DC Drives

What is a Drive and Electrical Drives

A drive is an electrical or electronic device used to control the speed and motion of electrical machines such as motors and robots etc. The device used for motor speed control is known is an electrical drive. They are constant and variable speed controller and widely used in industrial automation.

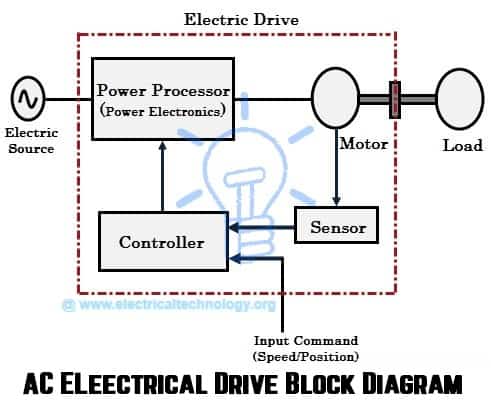

Following is the basic electrical drive diagram.

There are mainly two basic types of electric drives as follow:

- AC Drives

- DC Drives

Related Post: Comparison between AC and DC Transmission System

What is AC Drive?

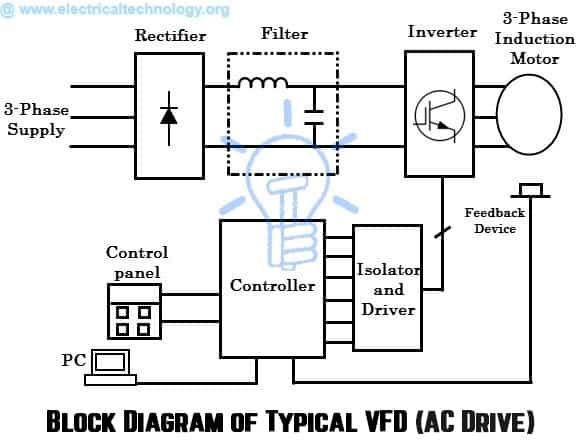

AC drive (alternating current drive) converts the AC supply to the DC using converter circuits based on rectifier and invert it back to the AC from DC using inverter to control the speed of electric motors especially three phase motors.

AC Supply → Converted to DC → Again Inverted to AC → Electric Motor

AC drive is also known as VFD (variable frequency drive), VSD (variable speed drive) or ASD (Adjustable speed drive).

The different types of AC drives operate on the same principle i.e. they convert the fixed amount of input voltage and frequency into the variable voltage and frequency output to control the motion of AC motors. Below is the basic block diagram of AC drive.

- Related Post: AC or DC – Which One is More Dangerous And Why ?

What is DC Drive?

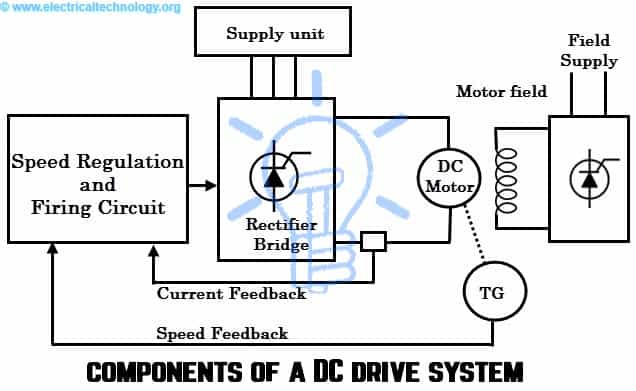

A DC drive (direct current drive) is a DC motor speed control system which convert the input AC supply to the DC using converter circuit based on rectifier (diodes and thyristors) to control the speed of DC motors.

Earlier, the variable DC voltage was generated by DC generators to control the speed of a DC motor. Nowadays, thyristors are used to convert the AC to the DC while mercury arc rectifier and thyristor converters are also used for the same purpose.

There are additional two types of DC drives viz:

- Analog DC Drives

- Digital DC Drives

Following is the basic block diagram of a typical DC drive.

Comparison between AC and DC Drives.

Below is the comparison chart showing some differences between AC and DC drives.

| Characteristics | AC Drives | DC Drives |

| Definition | AC drives (also known as VFD) convert the AC supply to DC using converter (rectifier) and invert it back from the DC to the AC using inverter to run the AC motors. | DC drives only convert the input AC supply to the DC using converter circuit based on rectifier to run the DC motors. |

| Control | AC drives control AC output from AC input. | DC drives control DC output from AC input. |

| Main Supply & Voltage | AC Drives run by AC power supply i.e. single phase and three phase AC voltages. | DC Drives run by DC power supply i.e. Batteries and supplies sources of DC voltages. |

| Self Start | Not self starting | Self Starting |

| Circuit Design | The circuit design of AC drives is little bit complex due to the inverter and converter which convert AC to DC and invert back DC to AC then. | The circuit design of DC drives is less complex due to the single power conversion i.e. It converts AC to DC only once. |

| Power and Control Circuits | AC drives power and control circuits are complex in design as compared to the DC drives. | DC drives power and control circuits are simple in design as compared to the AC drives. |

| Breaking / Acceleration | The breaking and acceleration mechanism of AC drives can be controlled by changing the supply frequency (FS). | The breaking mechanism of DC drives can be control by applying resistance at rotor side. |

| Speed Control | Speed control is done by changing the supply frequency. | Speed control is done by armature and field control. |

| Speed Limitation | Maximum speed can be achieved. | The speed is limited because of commutator used in the motors for commutation. |

| Motor Speed in RPM | Up to 10k RPM | Up to 2.5k RPM |

| Speed Regulation | ~1% speed regulation is achievable in motors run by AC drives. | 1% speed regulation is not possible to achieve in motors run by DC drives. |

| Speed Torque | It is complex to adjust the speed torque curves. | It can be achieved easily. |

| Starting Torque | Low | High |

| Inverter / Converter | AC drives have both inverter and converter. | DC drives have converter and chopper circuits. It doesn’t need an inverter. |

| Commutator and Slip Rings | No need of commutation but slip rings in AC drives. | No slip rings but Commutation is needed in DC drives. |

| Rectification | No need of rectification circuit. | Rectifier circuit is must. |

| Battery Operation | AC drives won’t be connected directly to the batteries as some additional components and circuits are needed to do so. | DC drives can be connected and run directly through batteries (providing DC voltage). |

| Transformer | AC drives can be directly connected to the transformer (mains supply). | In DC drives, transformer is needed at voltage higher than 100V. |

| Power usage | AC drives consume less power as compared to DC drives. | DC drives consume more power as compared to AC drives. |

| Brushes Life span | High (about 10k hours) | Low (about 3k hours) |

| Noise | Operation of AC drives is noisy. | Operation of DC drives is less noisy. |

| Harmonics | Inverter used in AC drives produces harmonics on both side i.e. supply and load. | Converter used in DC drives doesn’t generate harmonics. |

| Spark | AC drives are spark free and can be used in wet environment. | DC drives can’t be used in wet areas due to generated spark in the burses. |

| Dynamic Response | High | Low |

| Maintenance | Less | More and frequent |

| Size, Weight & Power Rating | Large | Small |

| Cost | AC drives are more expensive while the motors used in AC drives are less expensive e.g. squirrel cage motor. | DC drives are less expensive while the motors used in DC drives are little bit expensive. |

| General uses | AC drives used in almost all areas with vast applications. | DC drives are used in few areas as compared to AC drives. |

| Applications | Generally, AC drives used for AC motors. They are used to control the speed of AC motors. | Normally, DC drives used for DC motors. They are used to control the speed of DC motors. |

- Related Posts: Can We Use AC Circuit Breaker for DC Circuit & Vice Versa?

Advantages of AC and DC Drives:

Advantages of AC Drives:

- They are low cost as well as conventional.

- They need less maintenance in case of AC motors.

- AC motors are commonly available and less expensive. They are lighter in weight in smaller in size as compared to the DC motors.

- High speed due to to no brush and commutation problem

Advantages of AC Drives:

- DC drive technology is efficient, reliable, cost effective, operator friendly and relatively easy to implement as compared to DC drive systems.

- DC drives are less expensive and complex due to the single conversion i.e. AC to DC conversion.

- DC drive provides many advantages over AC drives, especially for regenerative and high power applications.

- DC drives have been widely used in industrial drive applications in order to offer very precise control

- Less noisy operation as compared to the AC motors.

- DC motors are self starting machines with high starting and accelerating torque.

Related Posts:

- Difference Between Microprocessor and Microcontroller

- Difference Between Electric Current and Electric Charge

- Difference Between Current and Voltage

- Difference Between MCB, MCCB, ELCB & RCD Circuit Breakers

- Difference Between Electric and Magnetic Circuit

- Difference Between EMF and MMF

- Difference Between Single Phase & Three Phase Induction Motor

very informative i have learned a lot thanx …please correct (AC drives not AD drives)

They are not the same between AC and DC

1) AC serious inverter from most of producers has “auto start” function setting for auto-restart.

2) AC squirrel cage motor doesn’t have brushes. 10-25 K working hours (acc. producer) is about lifespan of bearings.

(from certain size (45-75kW (depend on producer of VFD) and higher) motors for drive with VFD must be with some special bearings…)

3) Special AC motor is able up to ~24 Krpm. Simple one squirrel cage motor is able just according installed bearings abilities. Usually up to 4,5k rpm. Also there issue about lose of torque, because main supply standard is 400-420VAC (three phase) and for increase the speed need higher speed in proportions of increase frequency.