DC Machine – Construction, Working, Types and Applications

Construction, Classification, and Applications of DC Machine

According to the source of supply, electrical machines are classified into two types; AC machine and DC machine. For example, DC Motors, DC Generator etc.

What is a DC Machine?

A DC machine is an electromechanical device that is used to convert electrical energy into mechanical energy or vice versa.

The DC machine used to convert electrical energy into mechanical energy, which is known as DC motor and the DC machine used to convert mechanical energy into electrical energy, which is known as DC generator. The same machine can be used either as a motor or generator. The construction is same for DC motor and DC generator.

Working of DC Machine

The working principle and operation of a DC machine is based on an effect when a current carrying conductor coils laying in a magnetic field, the magnetic field produces a mechanical force on it known as torque which rotates the conductor coils in magnetic field. The direction of this produced torque can be found by the Fleming’s left hand rule (thumb is the force). The generated force can be calculated as follow.

F = BIL

Where:

- F = Magnitude of the generated force

- B = Flux density

- I = Current

- L = Length of the conductor

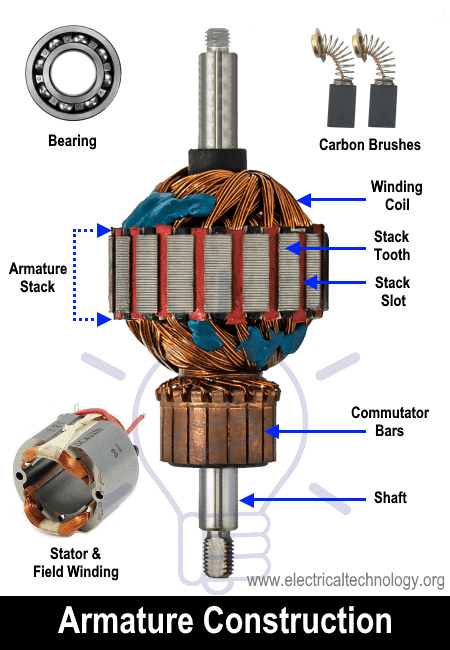

Construction of DC Machine

The DC machine consists of Yoke, Pole, and Pole shoe, Armature core, Field Winding, Armature Winding, Commutator, Brushes, shaft, and Bearings. Let’s explain each part in detail with applications.

- Yoke or Frame

The yoke is also known as the frame. It covers the internal parts of the machine. The yoke is made up of low reluctance magnetic material like iron and silicon steel. Generally, the yoke is made up of iron because iron is cost-effective material than steel.

The yoke is used to provides mechanical protection to the machine. The second application of yoke is that it provides a low reluctance path to the flux. So, flux completes its path through the yoke.

- Pole and Pole shoe

The field winding is placed on a pole. When current passes through the field winding, it will create an electric magnetic field and behaves as an electromagnet. The pole shoes expand flux in the entire machine.

To reduce the eddy current losses, the pole and pole shoes are laminated. For a small machine, the pole is not necessary to laminate. It is made up of thin cast steel.

The pole is used to provide housing for the field winding and produce magnetic flux inside the machine. The pole shoes are used to provide support to the field winding and not to slip from the pole.

- Field Winding

It is winding wounded on the pole is known as the field winding. External DC source or the output of the machine is used to excite the field winding.

It is made up of copper and aluminum. In most of the case, the winding is made up of copper but when the cost is a consideration, aluminum is used.

When DC current passes through the coil, it will generate the electromagnetic field (EMF). And it will magnetize the pole and produce the magnetic flux. The flux produced by the pole is directly proportional to the field current. And flux is more enough to cross the air gap between armature and pole shoes.

- Armature Core

The armature core is cylindrical in shape and connected by a key with the shaft. So, it is a rotating part of the DC machine.

The armature core consists of a number of slots on its outer periphery. It is made up of low reluctance and high permeability material like cast iron or cast steel. The armature core is laminated to reduce the eddy current.

The holes are provided on the armature core to release the heat of the machine. The armature slots are used to house the armature winding.

- Armature Winding

The armature winding is placed on the slots of the armature core. It is made up of copper. The armature winding links with the magnetic flux and induce a rotating magnetic flux.

According to the connections, there are two types of windings; Lap winding and Wave winding

- Lap winding

In lap winding, the armature conductors are divided into groups of a number of poles P. All conductor groups are connected in parallel and in one group, all conductors are connected in series.

For lap winding, the number of a parallel path (A) is the same as the number of poles (P). Therefore, in lap winding, the number of parallel paths is more. And due to this, it is capable of supplying larger load current.

So, lap winding is used for low voltage high current applications.

- Wave Winding

In wave winding, all conductors are connected in series and it forms a single loop. For wave winding, irrespective of the number of poles, the number of parallel paths is always two.

So, in wave winding, a smaller number of parallel paths available compared to the lap winding. The wave winding is used for high voltage low current DC machine.

- Commutator

The commutator is mounted on the shaft of a machine. The armature conductors are rotating. The commutator is used to connects the rotating armature conductor with a stationary external circuit.

It converts alternating torque produced in the armature into unidirectional torque. In other words, it converts AC torque into DC torque. So, it works similar to the rectifier.

It is made up of a number of segments of hard drawn copper to reduce tear and were. Because it connects the rotating part to a stationary part. All segments are insulated from each other by the thin layer of mica, paper or plastic insulators.

- Brushes

The commutator connected the external circuit via brushes. The brushes are used to carry current from the armature conductors.

In most of the cases, brushes are made up of carbon for a small machine and electro-graphite brushes used for the large machines.

The brushes are held the surface of the commutator by springs and rectangular in shape.

- Shaft

The shaft used to transfer mechanical power. If the machine is used as a DC motor, mechanical power is transferred from the motor to load. And if the machine is used as a DC generator, mechanical power is transferred from prime mover to the machine.

- Bearing

The bearings are used at the end of the shaft. The friction between the rotating part and the stationary part is reduced with the help of bearings.

The bearing is made up of any hard material like carbon steel. The ball type or roll type barring is used in the DC machine.

Classification of DC Machine

There are different types of DC machines like series, shunt, short shunt compound and long shunt compound.

According to the field excitation method, the DC machines are classified as;

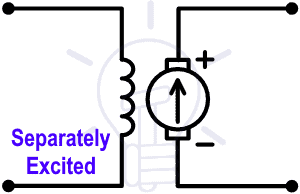

- Separately Excited DC Machine

- Self-Excited DC Machine

Separately Excited DC Machine

In this type of machine, the field winding is electrically separate from the armature winding. There is no physical connection between the field winding and the armature winding.

In separately excited machines, the field winding is supplied from a separate power source.

Self-excited DC Machine

In this type of DC machine, the field winding and armature winding are connected with each other. The performance characteristic of a machine depends on the connection between the field winding and armature winding.

According to the connection between field winding and armature winding, the DC machines are classified as;

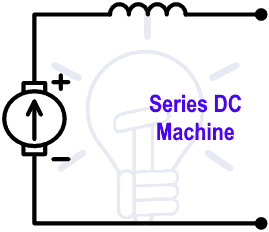

- Series Wound DC Machine

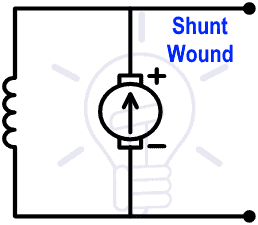

- Shunt Wound DC Machine

- Compound Wound DC Machine

Series DC Machine

In this type of DC machine, the field winding is connected in series with the armature winding. Because of the series connection, the entire load current (armature current) will pass from the field winding. And this current is high.

So, the series field winding is designed with a smaller number of turns of thick wire to reduce the resistance.

Shunt Wound DC Machine

In this type of DC machine, the field winding is connected in parallel with the armature winding. Because of the parallel connection, full voltage is applied to the field winding. Therefore, shunt winding is designed with a large number of turns with high resistance.

The current flow through the field winding is very small. It is just 5% of the rated armature current.

Compound Wound DC Machine

In this type of DC machine, two field windings are used. One winding is connected in series and second winding is connected in parallel with the armature winding.

The compound Wound DC Machine is also classified into two types;

- Short Shunt

- Long Shunt

Short Shunt

If the field winding is connected in parallel with only the armature winding, the machine is called a Short shunt compound wound DC machine.

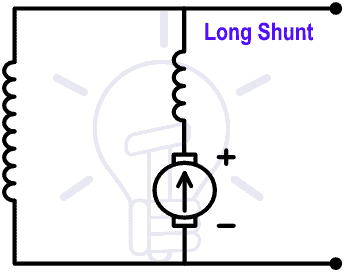

Long Shunt

If the field winding is connected parallel with a combination of series field winding and armature winding, the machine is called a Long-shunt compound wound DC Machine.

Applications of DC Machines

The use of electrical energy increases day by day. And because of that, the use of electrical machines is also increasing.

Generally, the DC machines are used in supplying excitation of an alternator and it is also used in many applications like welding process, variable-speed motor drives and electrolytic and electroplating process.

Small DC machines are used as a control device such as speed sensing, positioning, and tracking.

Application of DC Machine as a Motor

The DC motors are divided into three types; Series motor, Shunt motor, and Compound motor.

- Series Motor

The series motors are used in the application where high starting torque is necessary and speed variation is possible.

Example- Vacuum cleaner, Air Compressor, Cranes, Traction system, etc.

- Shunt Motor

The shunt motor is used in the application where starting torque is not needed more and running on the constant speed.

Example- conveyer, Lift, Fans, Lathe machine, Spinning machine, centrifugal pump, etc.

- Compound Motor

The compound motors are used in applications where higher starting with constant speed is required.

Examples- Rolling mills, Elevators, Conveyer, Presses, etc.

Application of DC Machine as Generator

The DC generators are classified as Separately excited DC generator, Shunt-wound, and Series-Wound generator.

- Separately excited DC Generator

This type of DC generator is used for testing in laboratories. Because it has a wide range of voltage input. It is also used as a supply to DC motor.

- Shunt-wound Generator

This type of generator used to charge a battery and provide excitation to the alternator. This type of generator also used for lighting purposes.

- Series-wound Generator

Series-wound generators are used in locomotive for providing field excitation current as well as for regenerative braking. In a distribution power system, it is used as a booster.

Related Electric Motors Posts

- Servo Motor – Types, Construction, Working, Controlling & Applications

- Brushless DC Motor (BLDC) – Construction, Working Principle & Applications

- Stepper Motor – Types, Construction, Operation & Applications

- Motor Starter – Types of Motor Starters and Motor Starting Methods

- Three Phase Motor STAR/DELTA Starter Wiring

- Direct Online Starter – DOL Starter Wiring Diagram for Motors

- Why We Need to Install a Starter with a Motor?

- What is Motor Efficiency & How to improve it?

- Cable Size Calculation for LT & HT Motors

- Voltage And Power Equations of a DC Motor

- AC Drive – Working and Types of Electrical Drives & VFD

- DC Drive – Working and Types of DC Drives

- Speed Control of DC Motor – Voltage, Rheostatic & Flux Control Methods

- Electric Motors Symbols