How to Control a Dual/Tap-Wound 3-Phase Motor for 2-Speed and 1-Direction using Dahlander Connection?

Three-phase motors are widely used in industrial applications due to their efficiency and robustness. Often, there’s a need for controlling the speed of these motors while maintaining a single direction of rotation. This wiring tutorial shows how to control a tap-wound 3-phase motor for two-speed and one-direction using Dahlander connection for contactors with the help of schematic, power, control and wiring diagrams.

Two-Speed Motor Control:

Two-speed control of a three-phase motor involves running the motor at two different speeds, often referred to as high speed (HS) and low speed (LS). This is achieved by connecting the dual or tap wound motor’s winding in a specific configuration (Dahlander connection) to adjust the magnetic field and, consequently, the motor’s speed.

The two-speed control is usually accomplished by changing the arrangement of the motor windings from the main to star (Y) connection and delta (Δ) connection, altering the impedance and hence the speed.

Related Posts:

- Two-Speed, Two-Directions, 3-Phase Motor – Power & Control Diagrams

- Three-Speed, One-Directions, 3-Phase Motor – Power & Control Diagrams

Components Needed

- Three-Phase Dual / Tap-Wound Motor

- 3 Nos. of Contactor

- Thermal Overload Relay

- 3-P MCCB

- 2-P MCB

- 3 Nos. of pushbuttons

- Single-Phase & Three Phase Supply

- Wires & Cables

Wiring & Control of Dual/Tap Wound Motor for 2-Speed Operation

At the initial stage, all contactors are de-energized.

- When K1 is energized, the motor runs at low speed.

- When K2 and K3 are energized, the motor runs at high speed.

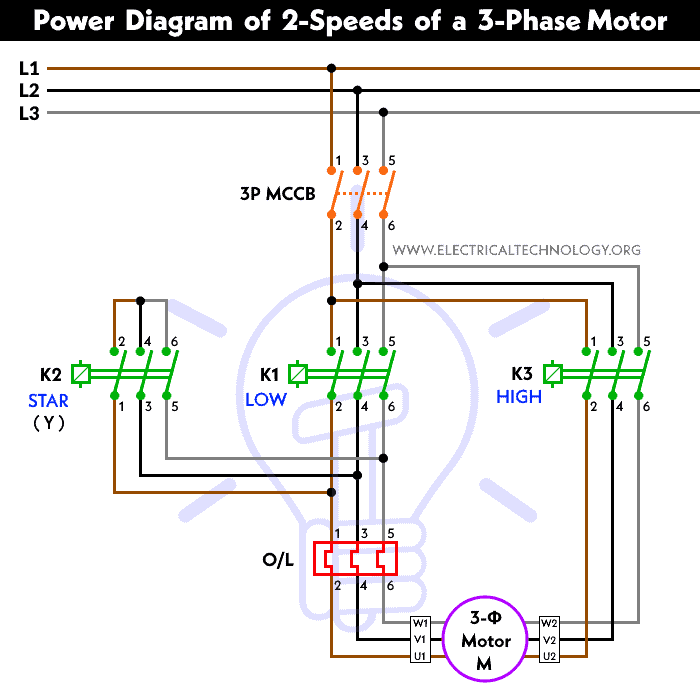

Power Diagram

Schematic Wiring Diagram

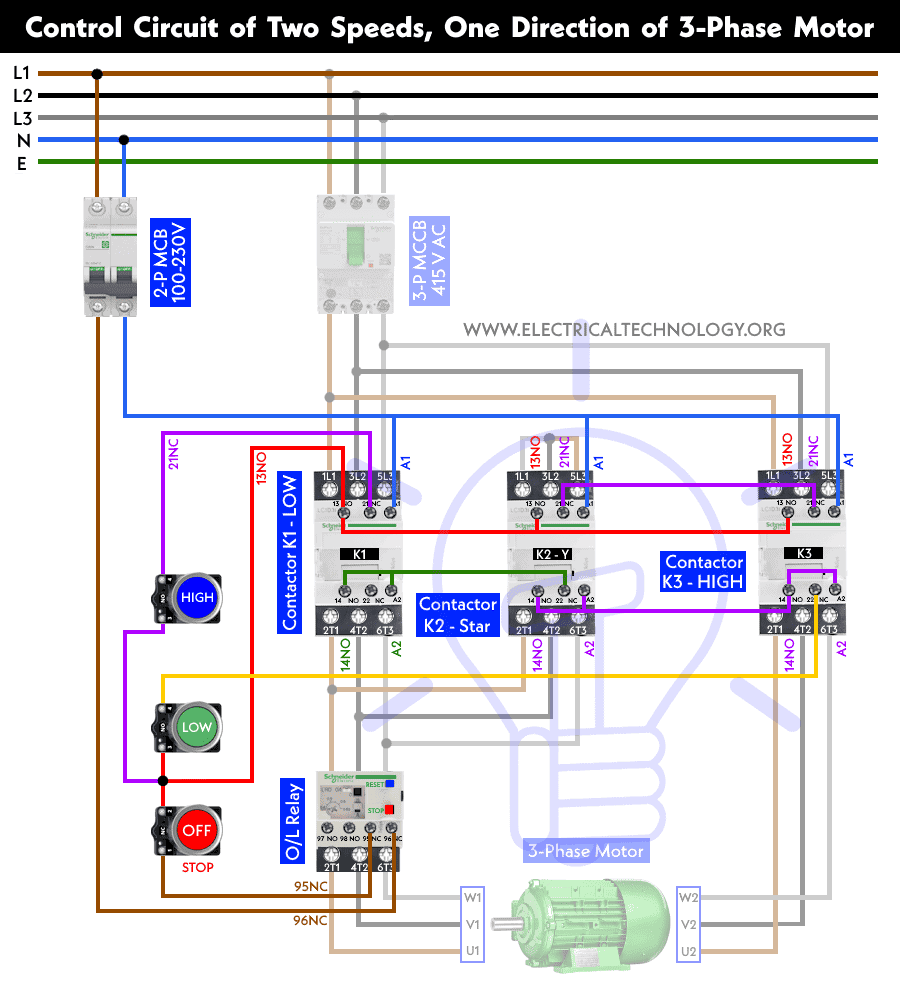

Control Wiring Diagram

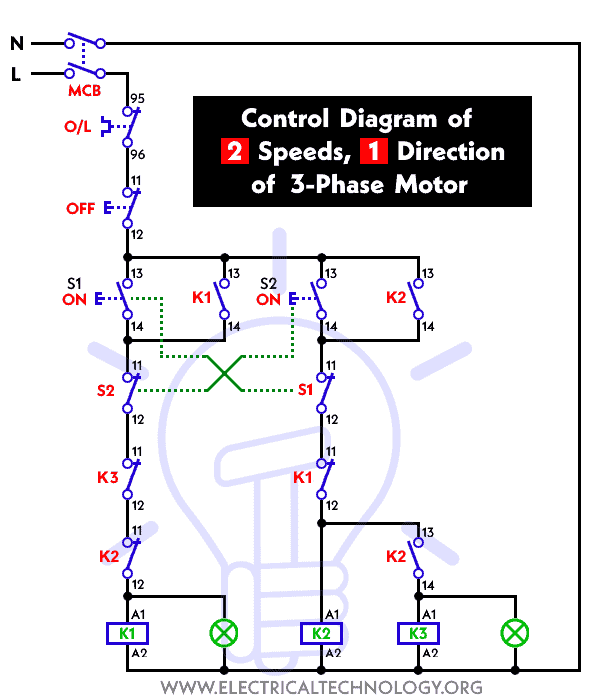

Control Circuit Diagram

Construction of the Power & Control Circuit:

To achieve two-speed, one-direction control of a three-phase motor using contactors, follow these steps:

Power & Control Circuit Diagram

Draw a schematic diagram and wire the power and control circuit as shown in the figures below. This circuit will consist of a power supply, a low speed contactor (K1), high-speed contactors (K2 and K3), a thermal overload relay (OLR), and the three-phase tap wound motor.

Low-Speed Contactor (K1):

The main contactor for low speed (K1) connects the motor to the power supply. When energized, it completes the circuit and allows current to flow through the motor windings. When the K1 is energized, the motor runs at low speed.

The K1 is controlled by a start pushbutton. If you release the pushbutton after pressing it, the contactor K1 is still energized. Thanks to the interlocking via auxiliary contacts. ,

High-Speed Contactor (K2 & K3):

The high-speed contactor (HSC) and low-speed contactor (LSC) are connected in parallel with each other. These contactors control the motor’s speed by switching between the star (Y) and delta (Δ) configurations of the motor windings. When the K2 and K3 are energized, the motor runs at high speed.

Thermal Overload Relay (OLR) The thermal overload relay protects the motor from overheating. It measures the motor’s current and trips if the current exceeds a predefined value, preventing motor damage. It’s wired in series with the K1 control circuit.

Control Logic:

Design a control logic that ensures the K1 is energized only K2 and K3 are de-energized by interlocking, preventing both contactors from being energized simultaneously. This prevents a short circuit in the motor windings due to incorrect wiring.

Control Inputs Connect start/stop. LOW and HIGH pushbuttons to the control circuit to initiate and halt motor operation. Connect these buttons in series with the K1 and O/L relay coil.

Working & Operation of Two-Speed Motor Control

This control circuit includes three contactors and three push buttons (Stop, S1, and S2). Pushbuttons S1 and S2 each have two contact blocks (one NO and one NC). Let’s analyze the circuit when we press S1 for slow speed.

Low Speed

- The contacts in parallel to K1 change their state from open to closed.

- Simultaneously, the S1 and K1 on the right side change their state from closed to open.

- As a result, only K1 is energized, and the motor runs at low speed.

- If the pushbutton is released by the operator, the K1 contactor will remain energized due to interlocking via auxiliary contacts.

High Speed

- When S2 is pressed, the contacts of K2 close from an open state, energizing the K2 contactor.

- The auxiliary contacts close and energize the K3 contactor.

- This happens because the auxiliaries of K2 and K3 contactors are energized.

- Consequently, the contacts change their state from closed to open on the left side.

- If the operator releases the S2 pushbutton, the motor continues to run at high speed.

Related Posts:

- Star-Delta (Y-Δ) 3-phase Motor Starting Method by Automatic star-delta starter with Timer.

- Three Phase Motor Connection STAR/DELTA Without Timer – Power & Control Diagrams

- Three Phase Motor Connection Star/Delta (Y-Δ) Reverse / Forward with – Timer Power & Control Diagram

- Starting & Stopping of 3-Phase Motor from more than One Place Power & Control diagrams

- Control 3-Phase Motor from more than Two buttons – Power & Control Diagrams

- ON / OFF Three-Phase Motor Connection Power & Control Schematic and Wiring Diagrams

- Three Phase Motor Connection Reverse and Forward – Power and Control wiring diagrams

- Three Phase Slip Ring Rotor Starter – Control & Power Diagrams

- Even Motor Power & Control Circuit Diagrams for 3-Phase Motor

Why Does an Electric Tester Not Work in DC Circuits?

Why Does an Electric Tester Not Work in DC Circuits? Rotor Balancing in the Motors – Types, Methods and Importance

Rotor Balancing in the Motors – Types, Methods and Importance Difference Between Static Balancing and Dynamic Balancing

Difference Between Static Balancing and Dynamic Balancing What are the Cuts on the Rotor of Motor’s Armature?

What are the Cuts on the Rotor of Motor’s Armature? Why Do Wind Turbines Have 3 Blades Instead of 2 or 5?

Why Do Wind Turbines Have 3 Blades Instead of 2 or 5? How to Calculate the Number of Panels for a Load without Battery Backup?

How to Calculate the Number of Panels for a Load without Battery Backup?