Miniature Circuit Breaker(MCB – Construction, Operation, Types and Applications

Introduction to Miniature Circuit Breakers (MCBs)

All fuses should be replaced with MCBs (Miniature Circuit Breakers) for enhanced safety and control once they have fulfilled their purpose. Unlike a fuse, an MCB operates as an automatic switch that opens in the event of excessive current flowing through the circuit. Once the circuit returns to normal, it can be reclosed without the need for manual replacement.

MCBs are primarily used as alternatives to fuse switches in most circuits. Nowadays, a wide variety of MCBs with breaking capacities ranging from 10KA to 16KA are used in domestic, commercial, and industrial applications, serving as reliable means of protection.

Miniature circuit breakers (MCBs) are compact in size and are designed to fit into standardized electrical panels and distribution boards. They work by detecting abnormal levels of current flowing through the circuit and automatically interrupting the flow of electricity to prevent damage to the circuit and connected devices. MCBs can be reset after they trip, unlike fuses which must be replaced. They are an important component of electrical safety systems in residential, commercial, and industrial buildings.

What is a Miniature Circuit Breaker (MCB)?

An MCB, or Miniature Circuit Breaker, is an electromechanical device enclosed in molded insulating material. Its main function is to automatically open the connected circuit when the flowing current exceeds its set value. It can also be manually operated to switch the connected circuit ON and OFF, similar to a standard switch, if necessary.

An MCB, or Miniature Circuit Breaker, is an electromechanical device designed to automatically protect electrical circuits from short circuit, overloads, and overcurrents.

A miniature circuit breaker (MCB) operates using electromagnetism to automatically break the circuit in case of short circuit or overload faults. It can also be manually operated by a person to switch the connected circuit on or off.

Following is the generic symbol used for circuit breakers.

MCBs are time-delay tripping devices in which the magnitude of overcurrent controls the operating time. This implies that they operate when overloads persist long enough to pose a danger to the protected circuit.

As a result, MCBs do not respond to transient loads, such as switch surges and motor starting currents. Generally, they are designed to operate in less than 2.5 milliseconds during short-circuit faults and in the range of 2 seconds to 2 minutes in the case of overloads, depending on the current level.

The typical external appearance of an MCB is shown in the figure. MCBs are manufactured in various pole versions, including single, double, triple, and four-pole structures, each with different fault current levels.

Most commonly, MCBs are interconnected to create two and three-pole versions, ensuring that a fault in one line breaks the complete circuit, providing complete circuit isolation. This feature is particularly helpful in the case of single phasing in three-phase motor protection.

These devices are rated at 220V for DC supply and 240/415V for AC supply (single and three-phase) with different short circuit current capacities. Typically, single-phase devices have a load current range of up to 100A. Some MCBs have the facility to adjust their tripping current capacity, while others are fixed for specific load currents and short circuit ratings.

MCBs serve multiple functions, such as local control switches, isolating switches against faults, and overload protection devices for installations or specific equipment and appliances.

Construction of MCB

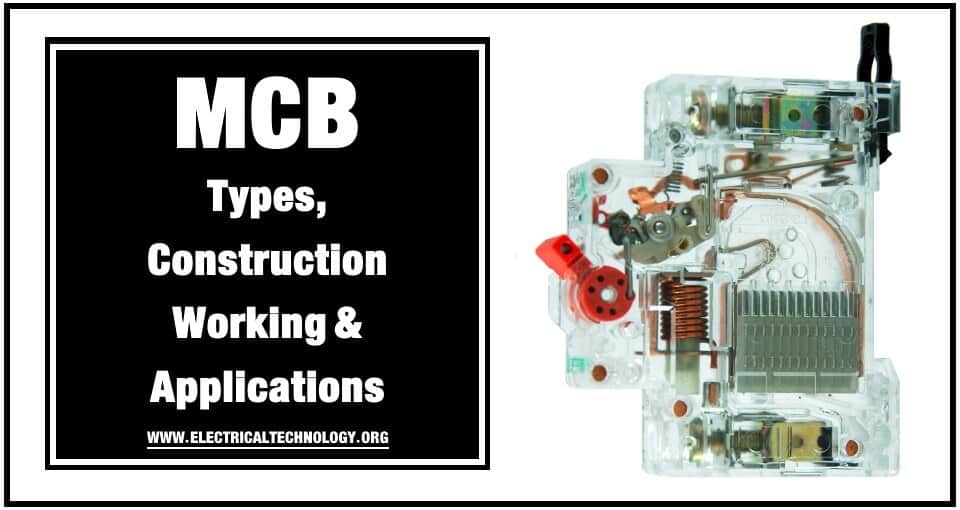

An MCB is encased in molded insulating material, providing a mechanically strong and insulated housing.

The switching system consists of a fixed and a moving contact to which incoming and outgoing wires are connected. The metal or current-carrying parts are made of electrolytic copper or silver alloy, depending on the rating of the circuit breaker.

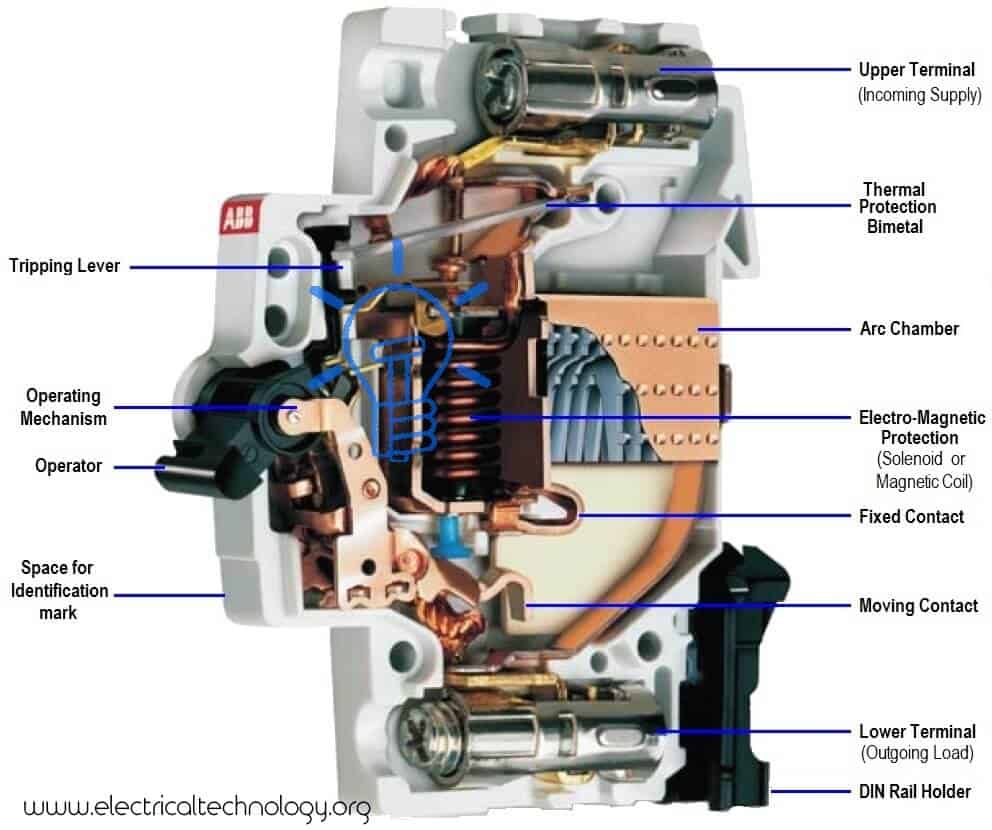

The above fig shows the following parts and components inside an MCB (cross-sectional view)

- Operator (ON-OFF)

- Operating Mechanism

- Space for Identification mark

- Thermal Terminal (Incoming Supply)

- Thermal Bimetallic Protection

- Arc Chamber

- Electromagnetic Protection (Solenoid or Magnetic Coil)

- Fixed Contacts

- Moving Contacts

- Lower Terminal (Outgoing Load)

- DIN Rail Holder

Related Post: What is an RCD (Residual Current Device)? RCB and RCCB

As the contacts separate during an overload or short circuit situation, an electric arc is formed. All modern MCBs are designed to handle arc interruption processes, where arc energy extraction and cooling are provided by metallic arc splitter plates.

These plates are held in position by an insulating material. Additionally, an arc runner is provided to guide the arc produced between the main contacts.

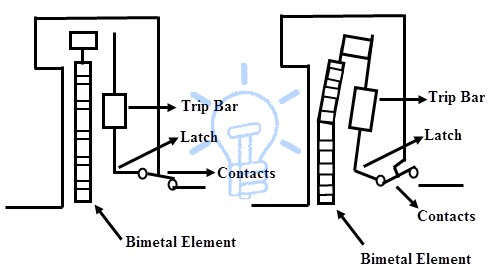

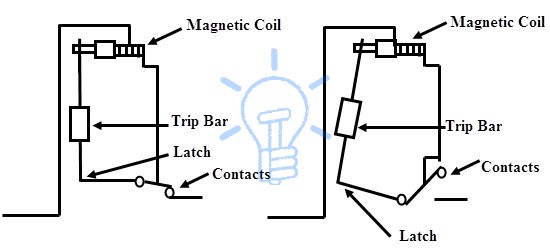

The operating mechanism incorporates both magnetic tripping and thermal tripping arrangements.

The magnetic tripping arrangement essentially comprises a composite magnetic system with a spring-loaded dashpot containing a magnetic slug in a silicon fluid, along with a normal magnetic trip. A current-carrying coil in the trip arrangement moves the slug against the spring towards a fixed pole piece. The magnetic pull is developed on the trip lever when a sufficient magnetic field is produced by the coil.

In the case of short circuits or heavy overloads, the strong magnetic field produced by the coils (solenoid) is sufficient to attract the armature of the trip lever, irrespective of the position of the slug in the dashpot.

The thermal tripping arrangement consists of a bimetallic strip around which a heater coil is wound to generate heat depending on the flow of current.

The heater design can be either direct, where current passes through a bimetal strip affecting part of the electric circuit, or indirect, where a coil of a current-carrying conductor is wound around the bimetallic strip. The deflection of the bimetallic strip activates the tripping mechanism in the case of certain overload conditions.

The bimetal strips are made up of two different metals, usually brass and steel. These metals are riveted and welded along their length. They are designed in such a way that they will not heat the strip to the tripping point for normal currents. However, if the current exceeds the rated value, the strip is warmed, bent, and trips the latch. Bimetallic strips are chosen to provide specific time delays under certain overloads.

Working and Operation of MCBs

Under normal working conditions, an MCB operates as a manual switch to turn the circuit ON or OFF. In the event of an overload or short circuit, it automatically trips to interrupt the current flow in the load circuit.

The visual indication of this trip can be observed by the automatic movement of the operating knob to the OFF position. This automatic operation in an MCB can be achieved in two ways, as we have seen in MCB construction: magnetic tripping and thermal tripping.

Under overload conditions, the current passing through the bimetal causes its temperature to rise. The heat generated within the bimetal itself is sufficient to cause deflection due to the thermal expansion of metals. This deflection further releases the trip latch, leading to the separation of contacts.

In some MCBs, the magnetic field generated by the coil causes it to exert pull on the bimetals, resulting in deflection that activates the tripping mechanism.

Under short circuit or heavy overload conditions, the magnetic tripping arrangement comes into play. During normal working conditions, the slug is held in position by a light spring because the magnetic field generated by the coil is not sufficient to attract the latch.

When a fault current flows, the magnetic field generated by the coil becomes strong enough to overcome the spring force holding the slug in position. Consequently, the slug moves and actuates the tripping mechanism.

Most miniature circuit breakers implement a combination of both magnetic and thermal tripping mechanisms. In both magnetic and thermal tripping operations, an arc is formed when the contacts start separating. This arc is then directed into arc splitter plates via an arc runner.

These arc splitter plates, also called arc chutes, transform the arc into a series of arcs while simultaneously extracting and cooling its energy. This arrangement ensures effective arc extinction.

Types of Miniature Circuit Breakers (MCBs)

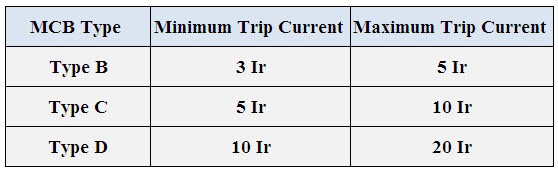

There are many types of circuit breakers while MCBs are classified into the following major types according to their instantaneous tripping currents. They are as follows:

Type A MCB

Type A MCBs, characterized by their tripping curve, are designed to provide protection against low-level overcurrents, making them suitable for circuits with a high capacitive load, such as those powering fluorescent lighting.

With a tripping current range of 2-3 times their rated current, Type A MCBs respond to overcurrent conditions at a relatively low threshold. This sensitivity is particularly advantageous in applications where electronic devices and sensitive equipment are prevalent

Type B MCB

Type “B” MCB will trip instantly at a rate of three to five times its rated current. These are normally used for resistive or small inductive loads where switching surges are very small. Therefore, these are suitable for residential or light commercial installations.

Type C MCB

Type “C” MCB will trip instantly at a rate of five to ten times its rated current. These are normally used for high inductive loads where switching surges are high such as small electric motors and fluorescent lighting.

In such cases, type C MCBs are preferred to handle higher values of short circuit currents. Therefore, these are suitable for highly inductive commercial and industrial installations.

Type D MCB

Type “D” miniature circuit breaker will trip instantly at a rate of ten to twenty five times its rated current. These are normally used for very high inductive loads where high inrush current is very frequent.

These are suitable for specific industrial and commercial applications. The common examples of such applications include x-ray machines, UPS systems, industrial welding equipment, large winding motors, etc.

Type G MCB

Type “G” MCBs are capable of providing protection against both overcurrent and earth fault current, similar to AFCIs and RCDs. They are typically required in specific areas of residential and commercial buildings to enhance electrical safety.

According to the NEC, they are required to be installed in bedrooms, living rooms, hallways, and circuits serving outlets and devices in certain other areas to detect and mitigate the risk of electrical fires caused by arcs in wiring.

Type H MCB

Type “H” MCBs are similar to Type G MCBs, designed to provide protection against both arc faults and overcurrents, especially in electrical systems powered by direct current (DC) supply.

Type K MCB

Type “K” MCBs are utilized to offer protection against overcurrents and short circuits in applications where the likelihood of faults is high, such as instances with high inrush currents in motors and inductive applications.

Type Z MCB

Type “Z” MCBs are designed for electronic circuits and sensitive equipment. They provide protection against low-level overcurrents and are suitable for circuits with semiconductor devices.

- Related Posts: What is an RCBO (Residual Current Breaker with Overcurrent)?

The above types of MCBs (based on tripping currents and curves) provide protection within one tenth of a sec. The minimum and maximum trip currents of these MCBs are given in a tabular form below, where “Ir” is the rated current of the MCB.

MCBs can also be classified based on the number of poles such as single pole, double pole, triple pole and four pole MCBs.

How to Select a Proper MCB for Different Loads?

Selecting the appropriate MCB for a specific application is a meticulous task essential for ensuring reliable protection against overloads and short circuits. Failure to choose an MCB in accordance with the circuit requirements may result in frequent and unwanted tripping.

Before delving into the details, it’s crucial to understand the differences between MCBs, MCCBs, ELCBs, RCBs, RCDs, or RCCBs circuit breakers, and to learn how to read the data printed on the MCB nameplate.

If the MCB is undersized (with a rating lower than the nominal load current), it can lead to frequent tripping, interrupting the current to the connected load, as the MCB’s nominal current is less than the load’s nominal current.

Conversely, if the MCB is oversized (with a rating higher than the nominal load current), the connected load may not be efficiently protected. In such cases, the MCB might not trip even when the load draws excessive current.

Three critical factors must be considered when selecting the proper MCB for a specific application.

Related Posts:

- How to Find the Proper Size of Circuit Breaker?

- How to Determine the Number of Circuit Breakers in a Panel Board?

1. Nominal Rating of the Circuit Breaker

This is the rated ampere current rating of MCB. This value must be lower than the current carrying capacity of wiring system and higher than or equal to the maximum full load current in the wiring system. Generally, this rating should be such that it can handle 125 percent of continuous load plus rating of non-continuous load. Typically this can be expressed as

Maximum full load current in the system ≤ Current rating of MCB ≤ Cable rating

2. kA rating or breaking capacity

This rating refers to the capability of MCB that can trip or interrupt the circuit under short circuit conditions. Its rating is expressed in Kilo Amps (KA). This rating must not be less than the prospective short-circuit current.

The prospective short-circuit current is the maximum current that exists in the circuit during short-circuit conditions. In residential installations 6KA MCB is sufficient while 10 KA or above rating MCB is needed for commercial and light industrial applications. Read more about Why Circuit Breaker Capacity Was Rated in MVA and Now in kA and kV?

3. Type of MCB

The type of MCB needed for a specific application is decided by operating characteristics such that various current ratings are required to operate the loads instantaneously. We have already mentioned various types of MCBs for different applications above.

Applications of an MCB (Miniature Circuit Breaker)

As the main functions and applications have already been described in the above statements, the fundamental purpose of an MCB is to protect a circuit (wiring used in residential, commercial, and industrial electrical panels, connected load, equipment, etc.) in the case of:

- Overload and Overcurrent Protection: MCBs are primarily used to protect electrical circuits from overloads. When the current exceeds the rated capacity of the MCB, it trips and interrupts the flow of electricity, preventing damage to the circuit and appliances.

- Short Circuit Protection: MCBs also protect against short circuits, which occur when there is a low-resistance connection between two conductors. The MCB detects the sudden surge in current and trips to prevent overheating and fire hazards.

- Ground Fault Protection: Some MCBs are equipped with ground fault protection, which detects leakage currents to the ground. This is important for safety, as it can prevent electric shocks and protect against insulation failure.

- Selective Coordination: MCBs are often used in coordination with other protective devices, such as fuses or larger circuit breakers, to ensure that the device closest to the fault opens first, minimizing downtime and damage.

- Remote Control: Some advanced MCBs (e.g. smart Wi-Fi circuity breaker) come with remote control capabilities, allowing for easier monitoring and control of electrical circuits in industrial or commercial settings.

- Related Post: Vacuum Circuit Breaker (VCB) – Construction and Working

FAQs

1. What is an MCB?

A Miniature Circuit Breaker (MCB) is an electromechanical device that protects electrical circuits from overloads, short circuits, and ground faults.

2. How does an MCB work?

An MCB works by detecting the amount of current flowing through the circuit. If the current exceeds the rated capacity of the MCB, it trips and interrupts the flow of electricity.

3. What are the types of tripping mechanisms in MCBs?

MCBs can have thermal, magnetic, or a combination of both tripping mechanisms. Thermal tripping responds to overloads, while magnetic tripping responds to short circuits.

4. What are the different types of MCBs based on tripping characteristics?

- Type B: for general purposes and slightly inductive loads.

- Type C: for resistive loads with moderate inrush current.

- Type D: for circuits with high inrush current, such as motor circuits.

5. What is the difference between an MCB and a fuse?

Below is the main difference between a fuse and a circuit breaker.

- An MCB can be reset after tripping, while a fuse must be replaced.

- MCBs offer more precise protection against overloads and short circuits compared to fuses.

6. How do you select the right MCB for a circuit?

Determine the maximum current the circuit will draw under normal conditions.

Consider the type of load (resistive, inductive, or capacitive) to select the appropriate tripping characteristic (B, C, or D).

7. Can MCBs be used for DC circuits?

Yes, there are MCBs specifically designed for DC circuits, with ratings suitable for DC applications.

8. Can MCBs be used as switches?

MCBs are primarily designed for protection and should not be used as regular switches. However, some MCBs have a switching mechanism for manual operation.

9. Can MCBs be used in wet or damp environments?

MCBs are not recommended for wet or damp environments. They should be installed in dry, well-ventilated areas.

10. What is the difference between a single-pole and a double-pole MCB?

A single-pole MCB protects only one live conductor, while a double-pole MCB protects both live and neutral conductors. Double-pole MCBs are used for 240V circuits, while single-pole MCBs are used for 120V circuits.

11. How do you test an MCB to ensure it is working correctly?

Use a multimeter to check the continuity of the MCB.

Verify that the MCB trips when the current exceeds its rated capacity.

12. Can MCBs be used in conjunction with residual current devices (RCDs) or GFCI?

Yes, MCBs and RCDs (same as GFCIs – Ground Fault Circuit Interrupter) can be used together for enhanced electrical protection. MCBs protect against overloads and short circuits, while RCDs protect against electric shocks.

Related Posts:

- HVDC Circuit Breaker – Types, Working and Applications

- Electronic Circuit Breaker – Schematic and Working

- Smart WiFi Circuit Breaker – Construction, Installation and Working

- Tripping Curves of Circuit Breakers – B, C, D, K and Z Trip Curve

- Difference Between MCB, MCCB, ELCB & RCD

- Difference Between Circuit Breaker and GFCI

- Difference between Circuit Breaker and Isolator / Disconnector

- Difference Between Relay and Circuit Breaker

- Can We Use AC Circuit Breaker for DC Circuit and Vice Versa?

- AFCI: Arc Fault Circuit Interrupter. Types, Working & Applications

- GFCI: Ground Fault Circuit Interrupter. Types, Working & Applications

- Fuse, Circuit Breaker and Protection Symbols

Why Does an Electric Tester Not Work in DC Circuits?

Why Does an Electric Tester Not Work in DC Circuits? Why Do The Positive And Negative Wires Spark When Touched?

Why Do The Positive And Negative Wires Spark When Touched? What are the Cuts on the Rotor of Motor’s Armature?

What are the Cuts on the Rotor of Motor’s Armature? Why Do Wind Turbines Have 3 Blades Instead of 2 or 5?

Why Do Wind Turbines Have 3 Blades Instead of 2 or 5? Difference Between Edge Triggering and Level Triggering

Difference Between Edge Triggering and Level Triggering Difference between Zener Diode and Avalanche Diode

Difference between Zener Diode and Avalanche Diode