Determine the Size of Earth Continuity Conductor, Earthing Lead & Earth Electrodes?

The sizing of earth continuity conductors, earthing leads, and earth electrodes for earthing or grounding purposes depends on the situation and wiring cables utilized in the system.

In this step-by-step guide, accompanied by a solved example for a premise or building, we will illustrate how to determine the correct sizing for protective earth conductors (CPC or ground wire), earth plates/electrodes/ground rods, earth leads, and continuity conductors in compliance with BS-7671, NEC, and IEC standards.

Note: As the terms Earthing and Grounding are used interchangeably, we will use both in the context of NEC and IEC for better understanding. Follow the local area codes such as NEC 250.52(A), 250.53, 250.66 250.122, IEC/BS EN 62561-2 and IEC (62305-3), BS-7671 and IEEE standards related to the grounding and earthing)

Sizing the Main Earthing Conductor

The cross-sectional area of the circuit protective cable (CPC), also known as the protective conductor, should adhere to Regulations 543.1.3 and 543.1.4 of IEC Regulation 543.1.1 in BS 7671:2018+A2:2022.

For copper wire, the cross-sectional area of the protective conductor should be at least 4mm2, as per Regulation 543.1.3, but not less than 2.5mm2. Section 544 provides guidance for selecting the appropriate cross-sectional area of the protective bonding conductor.

Regulation 542.3.1 applies when the protective or CPC conductor is buried in the ground.

To calculate the cross-sectional area of the protective conductor, using the reference formula from BS 7454:

Where:

- S = Nominal cross-sectional area of the conductor (mm2)

- I = RMS value of fault current (in amps) for a fault of negligible impedance

- t = Operating time (in seconds) of the protective device in case of a fault

- k = Constant factor based on resistivity, temperature coefficient, initial and final temperature, and heat capacity of the conductor material (Refer to BS 7671 Tables 54.2 to 54.6 for the value of k).

The most practicable method for determining the minimum cross-sectional area of the protective conductor relative to the line conductor is in compliance with BS 7671 Standard Regulation 543.1.4, along with associated tables such as Table 43.1 and Tables 54.2 to 54.6, as well as Table 54.7, as provided below:

| X-Section Area of Line Conductor (S) | Min. X-Sectional Area of the Related Protective Conductor | |

| When Conductor Material is Same for Line & CPC | When Conductor Material is Not Same for Line & CPC | |

| (mm2) | (mm2) | (mm2) |

| S ≤ 16 | S | (k1 ÷ k2) × S |

| 16 < S ≤ 35 | 16 | (k1 ÷ k2) × 16 |

| S > 35 | S ÷ 2 | (k1 ÷ k2) × (S ÷ 2) |

|

||

Good to Know

- According to NEC Table 250.122, the minimum wire size for a single equipment grounding conductor (EGC) is 4 AWG (21.15 mm²) copper (Section 392.10(B)(1)(c)).”

- In NEC (National Electrical Code) standards, the size of the ground wire conductor depends on various factors. Common sizes for residential grounding conductors include #10 AWG or #8 AWG for smaller branch circuits. For more details, refer to NEC sections 250.70 for Grounding Conductor Sizing and 250.122 for Size of Equipment Grounding Conductors.”

- According to IEC standards, the typical size of the bare copper wire used as an earth continuity conductor is 3 SWG (32 mm²).”

- Do not use a size smaller than 14 SWG (2.9 mm²) for the earth wire. Alternatively, copper strip can be used as an earth continuity conductor instead of bare copper wire, but only if recommended by the authorities.

Sizing of Main Earthing Conductor for PME

To determine the suitable size for the main protective conductor in the case of PME (Protective Multiple Earthing also known as TN-C-S PME), the cross-sectional area of the earthing conductor should comply with the requirements of Regulations 542.3.1 and 544.1.1.

The following summarized table, based on Table 54.8 of BS 7671:2018+A2:2022, shows the minimum cross-sectional area of the main protective bonding conductor and the applicable sizes of the PEN conductor, bonding conductor, and earthing conductor in TN-C-S PME earthing systems.

| X-sectional area of Copper Equivalent for PEN Conductor (mm2) | Min. X-sectional area of the Main Protective Bonding Conductor (mm2) |

| ≤ 35 | 10 |

| > 35 up to 50 | 16 |

| > 50 up to 95 | 25 |

| > 95 up to 150 | 35 |

| > 150 | 50 |

Sizing of Main Protective Conductor for PNB

To determine the appropriate size for the main protective conductor in the case of PNB (Protective Neutral Bonding, also known as TN-C-S PNB), the cross-sectional area of the earthing conductor should comply with the requirements of Regulation 543 of BS 7671.

As per Regulation 544.1.1 (when PME earthing isn’t used), the main protective bonding conductors must be at least half the size of the earthing conductor. If copper (or any other metal) conductor is used, the minimum size is 6mm2, and the maximum size is 25mm2 as shown in table (based on Table 5.1 from IET Guidance) below.

| X-Sectional Area of Line Conductor in mm2 | X-Sectional Area of Earthing Conductor in mm2 | X-Sectional Area of Main Protective Bonding Conductor in mm2 |

| 4 | 4 | 6 |

| 6 | 6 | 6 |

| 10 | 10 | 6 |

| 16 | 16 | 10 |

| 25 | 16 | 10 |

| 35 | 16 | 10 |

| 50 | 25 | 16 |

| 70 | 35 | 25 |

| 95 | 50 | 25 |

| 120 | 70 | 25 |

| 150 | 95 | 25 |

| 185 | 95 | 25 |

| 240 | 120 | 25 |

| 300 | 150 | 25 |

| 400 | 240 | 25 |

As per Standard BS 7671:2018+A2:2022, TN-S bonding and earthing can be employed for TN-C-S PBN installations, thereby reducing both time and costs due to the decreased use of copper materials.

Sizing Protective Earth Conductor & Earthing / Grounding Components

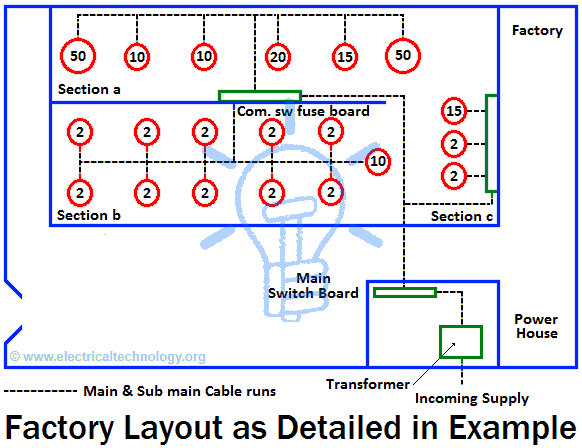

The following solved example (layout is shown below in fig 1) based on BS-7671 and associated tables will illustrate how to determine the appropriate sizes for earthing’s components such as protective earth conductor (ground wire), earth lead (earth continuity conductor) and earth electrode / ground rod in a specific installation, making the point easier to understand.

Example:

Find the proper size of earth conductor, earth lead and earth electrode for earthing and grounding system in the factory installations. Details and description of the given load (electric devices and equipment in the factory) as follow:

1. Motors

- 2 No of 50hp, 415V three phase induction motors and size of the cable connected to the motors is 19/.064.

- 1 No of 20hp, 415V, three phase induction motor and size of the cable connected to the motor is 7/.064.

- 2 No of 15hp, 415V, three phase induction motor and size of the cable connected to the motor is 7/.052.

- 3 No of 10hp, 240V, single phase induction motor and size of the cable connected to the motor is 19/.052.

- 12 No of 2hp, 240V, single phase induction motor and size of the cable connected to the motor is 7/.036.

2. Transformer

There is a 250kVA, three phase 11kV/400V (Step down) transformer installed in the factory which neutral have to be earthed. Size of the cables connected to LT (Low Tension) is 37/.083.

3. Water Level

Water level is deep about 30ft.

Solution:

Finding the Size of Earth Conductor:

Layout of the complete factory earthing and grounding system is shown in fig 2 below. Here, the biggest possible source of fault current is transformer, therefore, at least one earthing plate should be installed near to the transformer and the proper location for earth plate installation (for transformer) is shown in fig 2 (Position A).

Since the water level is deep about 30ft, therefore, we have to dig about 30ft coined and both of the plate can be installed in the same pit then (By doing so, we don’t need two pits as well as, it reduce the installation cost as well). However, for better safety purposes, another pit about 12ft can be dug (on Position B) near to position A for second earth plate installation. Also, make sure that water purring is possible when needed.

A connecting point near to main switch board is made at point C. The second point at D and third one at E which is right below the combination switch fuse board and above the cable ducting.

These points are connected via wires flowing through cable ducts. Since the example is fully related to the earthing of electrical apparatus only, therefore, there are two separately earth continuity conductor in whole factory (earth continuity conductors of other metalwork i.e. distribution fuse boards, switch fuses and other electrical wiring etc. are not shown in the fig due to complexity)

- Related Post: Types of Electrical Wiring

After proper selection of plates and connecting points, now we can find the proper size of earth continuity conductor and earth lead with the help of the following table no 1. In this table, suitable size of earth continuity conductor is given for each size of cable. For simplicity, the whole earthing scheme of the factory is divided in three sections.

Explanation of each section is as follow:

Section A:

According to table 1

- Earth continuity conductor to 50hp motor (19/.064 cable) = 4 SWG

- Earth continuity conductor to 20hp motor (7/.064 cable) = 10 SWG

- Earth continuity conductor to 15hp motor (7/.052 cable) = 12 SWG

- Earth continuity conductor to 10hp motor (19/.052 cable) = 6 SWG

In this section, the biggest motor is 50hp, therefore, the central pair of earth continuity conductor should able to pass any value of fault current produce in the motor. In this section, since each motor of 50hp is installed on the far end of the distribution system, therefore, the size of each earth continuity conductor around this section 4SWG. The proper sizes of earth continuity conductors for other small motors to the main pairs also given in table 2.2.

Section B:

According to the table, the earth conductor sizes are as follow for this section.

- Earth continuity conductor to 10hp motor (19/.052) = 6 SWG

- Earth continuity conductor to 2hp motor (7/.036) = 14 SWG

The distribution system in this section is designed such a way that the size of each earth continuity conductor (from 10Hp motor to the connecting point E) is 6 SWG but, for 2Hp motors, the size of earth conductor is 14SWG. There would be a safe path, if fault occurs at 10Hp motor side.

Section C:

The size of earth continuity conductors for this section is as follow:

- Earth continuity conductor to 5hp motor (7/.052) = 12 SWG

- Earth continuity conductor to 10hp motor (7/.036) = 14 SWG

The size of earth continuity conductor from 15Hp to connecting point D is 12SWG while for 2Hp (each) motor, the conductor size would be 14SWG.

Related Posts

- How to Find the Proper Size of Circuit Breaker? Breaker Calculator & Examples

- How to Find Voltage & Ampere Rating of Switch, Plug, Outlet & Receptacle

- How to Find The Suitable Size of Cable & Wire for Electrical Wiring Installation

Finding the Size of Earth Leads:

Now we can find the proper size of earthing leads. Since the cable size of transformer on L.T side is 37/.083. So we can use 3/0 SWG copper wire (or 3/16 x ¾ or 1/8 in) Copper strip. If fault occurs at transformer, then fault current will flow through the earth plat A or B or both at once and it depends on the earth resistance as well.

Therefore, the earth leads should able to pass the fault current. For this purpose, we should use 3/0 SWG for all earth leads from transformer to C, C to A, C to D, and D to B. Since the Transformer fault current will not flow in wires between E to D, therefore, it size should be 4SWG (which is equal to the big earth continuity conductor connected to E).

Finding the Size for Earth Plates & Earth Electrodes

Since both earth plates are below from water level, therefore, 2ft x2ft x 1/8 plate size is most suitable for each main and secondary plate. Continuity should be well after testing the system but also consider the earth resistance as well.

If the earth resistance increases than 1Ω, in that case, additional plates can be used in parallel with secondary plate to minimize the total resistance of earthing and grounding system.

Table 1. Earthing Conductors

Size of copper wire and Strip for earth continuity conductor and earth leads.

| Earthing Conductor

Size of Copper Wire and Strip for Earth Continuity Conductors and Earthing Leads |

|||||

| Cable Size | Earthing Lead Copper Wire | Earth Continuity Conductor | Copper Strip Size | ||

| SWG | Area | Number & Diameter of Wires | |||

| Sq. in | Inch. | Sq. in | Sq. in | ||

| 14 | 0.0015 | 1/.044 | 0.01 | 0.002 | ….. |

| 14 | 0.002 | 3/.029 | 0.01 | 0.002 | ….. |

| 14 | 0.003 | 3/.036 | 0.01 | 0.002 | ….. |

| 14 | 0.0045 | 7/.029 | 0.01 | 0.0045 | ….. |

| 14 | 0.007 | 7/0.36 | 0.01 | 0.0045 | ….. |

| 14 | 0.01 | 7/.044 | 0.01 | 0.0045 | ….. |

| 12 | 0.0145 | 7/.052 | 0.01 | 0.01 | ….. |

| 10 | 0.0225 | 7/.064 | 0.01 | 0.01 | ….. |

| 8 | 0.03 | 19/.044 | 0.01 | 0.01 | ….. |

| 6 | 0.04 | 19/.052 | 0.0225 | 0.0225 | ….. |

| 4 | 0.06 | 19/.064 | 0.0225 | 0.0225 | ….. |

| 2 | 0.1 | 19/.083 | 0.06 | 0.06 | ….. |

| 1/0 | 0.15 | 37/.072 | 0.06 | 0.06 | ¾ × 1/8 |

| 3/0 | 0.2 | 37/.083 | 0.1 | 0.1 | ¾ × 3/16 or 1×1/8 |

| ….. | 0.25 | 37/.093 | 0.1 | 0.1 | ¾ × ¼ |

| ….. | 0.3 | 37/.103 | 0.1 | 0.1 | 1 ×3/16 or 3/2×1/8 |

| ….. | 0.4 | 61/.093 | 0.1 | 0.1 | 1× ¼ |

| ….. | 0.5 | 61/.103 | 0.1 | 0.1 | 3/2×3/16 |

| ….. | 0.6 | 91/.093 | ….. | 3/2 × ¼ | |

| ….. | 0.75 | 91/.103 | ….. | 2×3/16 | |

| ….. | 1.0 | 127/.103 | ….. | 2 × ¼ | |

Here is a simplified version of the table if you need to download it for later use.

Table 2.

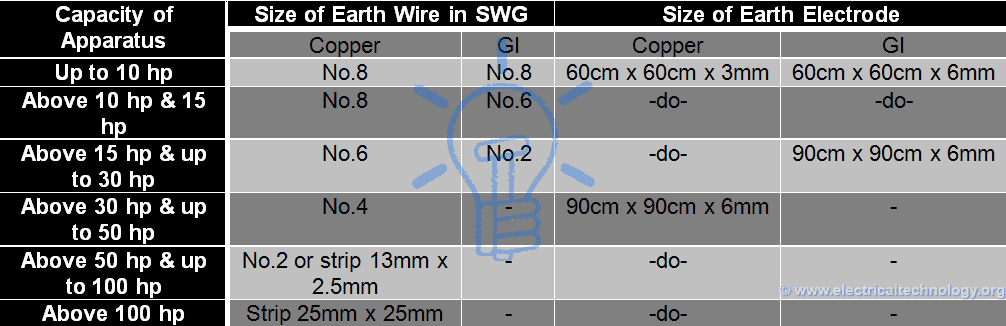

Size of Earth Wire in SWG and Earth Electrode for Motors and Other Electrical Apparatus, Devices and Equipment.

Note: Perform a continuity test for earthing installation to make sure everything is working as expected.

Related Posts:

- Difference Between Grounding, Earthing and Bonding

- Difference between Real Ground and Virtual Ground?

- Difference Between Neutral, Ground and Earth

- How to Find the Size of Earth Conductor, Earthing Lead & Earth Electrodes?

- Design of Grounding / Earthing System in a Substation Grid

- Different Types of Electrical Wiring

- Step by Step Home Electrical Wiring Installation Tutorials

- The purpose of Earth or Ground wire in overhead Transmission lines.

Why Does an Electric Tester Not Work in DC Circuits?

Why Does an Electric Tester Not Work in DC Circuits? Why Do The Positive And Negative Wires Spark When Touched?

Why Do The Positive And Negative Wires Spark When Touched? Rotor Balancing in the Motors – Types, Methods and Importance

Rotor Balancing in the Motors – Types, Methods and Importance Difference Between Static Balancing and Dynamic Balancing

Difference Between Static Balancing and Dynamic Balancing What are the Cuts on the Rotor of Motor’s Armature?

What are the Cuts on the Rotor of Motor’s Armature? Why Do Wind Turbines Have 3 Blades Instead of 2 or 5?

Why Do Wind Turbines Have 3 Blades Instead of 2 or 5?