Electrical Treeing in XLPE Insulated MV & HV Cables

(Manuel Bolotinha)

Nowadays XLPE (Cross-linkedpolyethylene) is the most used insulation material of medium and high voltage cables, which presents important advantages over PVC (Polyvinylchloride) and other insulations materials.

Main advantages of XLPE are:

- Thermal stability

- High dielectric strength and insulation resistance

- Lower losses (tan δ)

- Stability to ageing

- Allows more current carrying capacity

- Allows higher values of short-circuit currents.

Related post: MV & HV Cable Termination to Equipment & Joints

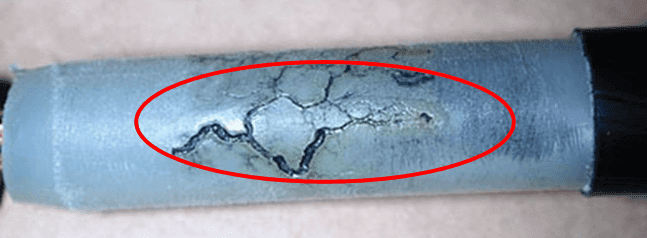

However, XLPE is very susceptible to treeing that is an electrical pre-breakdown phenomenon in solid insulation caused by partial discharge that progresses through the stressed dielectric insulation, in a path resembling the branches of a tree, as shown in Figure 1.

Figure 1 – Treeing in a XLPE insulated cable

- Related post : How To Locate Faults In Cables? Cable Faults, Types & Causes

Partial discharges are among the principal causes of catastrophic failures in cable terminations and joints. Main causes of discharges are deterioration of the insulation wall and joint defects.

Acoustic Emission techniques can be used for the detection of partial discharges in cables and a Partial Discharge Scanner (PDS), like the one shown in Figure 2, may be used for partial discharges monitoring.

Figure 2 – Partial discharge scanner

Also Read: Cables Feeder Protection – Faults Types, Causes & Differential Protection

Treeing of solid medium and high voltage cable insulation is a common breakdown mechanism and source of faults in power cables.

Electrical treeing first occurs and propagates when a dry dielectric material is subjected to high and divergent electric field stress over a long period of time and it is observed to originate at points where impurities, gas voids, mechanical defects, or conducting projections cause excessive electrical field stress within small regions of the dielectric.

This can ionize gases within voids inside the bulk dielectric, creating small electrical discharges between the walls of the void. An impurity or defect may even result in the partial breakdown of the solid dielectric itself.

Over time, a partially conductive, branching 3D tree-like figure is formed within the dielectric. At first, the figure is microscopic in size, and is called a water tree.

- Also Read: Types of Control & Communication Cables

The tree can grow to the point that it eventually causes complete electrical failure of the dielectric, at which point it is called an electrical tree.

This has been a long-term failure mechanism for buried polymer-insulated medium and high voltage power cables.

In a similar fashion, 2D trees can occur along the surface of a highly stressed dielectric, or across a dielectric surface that has been contaminated by dust or mineral salts. Over time, these partially conductive trails can grow until they cause complete failure of the dielectric.

Factors needed to be present in order for water trees to establish and grow in extruded cable insulation are:

- Electrical field: Is usually the applied operating voltage on the cable; if no voltage is applied to the cable, no water trees will form.

- Time: A relatively slow process, taking several years.

- Existence of water or moisture substance.

The most important measure to prevent treeing in XLPE it is required end sealing of cables in storage, to avoid moisture to enter into the cable.

Why Does an Electric Tester Not Work in DC Circuits?

Why Does an Electric Tester Not Work in DC Circuits? Why Do The Positive And Negative Wires Spark When Touched?

Why Do The Positive And Negative Wires Spark When Touched? What are the Cuts on the Rotor of Motor’s Armature?

What are the Cuts on the Rotor of Motor’s Armature? Why Don’t Bug Zappers and Fly Swatter Bats Kill Humans?

Why Don’t Bug Zappers and Fly Swatter Bats Kill Humans? Why Use VCB Circuit Breakers in HV Transmission, & Not ACB?

Why Use VCB Circuit Breakers in HV Transmission, & Not ACB? Electric Fence – Working, Types, Protection & Installation

Electric Fence – Working, Types, Protection & Installation